Silicon (Si) – Custom Machined Parts

Silicon is the most common semiconductor material. High-purity silicon is the material for both silicon wafers and semiconductor processing components to avoid particle and contamination.

Columnar crystal silicon is available in large sizes. It also has superior mechanical strength over a wide temperature range. Moreover, the machinability of columnar crystal silicon is better than that of single crystal silicon, and can be machined with less chipping and cracking.

Silicon Properties

| Property (Unit) |

Vickers Hardness HV(GPa) |

Flexural Strength (MPa) |

Melting Point (℃) |

Coefficient of Thermal Expansion(×10-⁶/℃) | Thermal Conductivity(W/(m・K)) | Volume Resistivity (μΩ・㎝) |

Purity (%) |

Doping |

|---|---|---|---|---|---|---|---|---|

| Structure & Chemical Formula | ||||||||

| Single Crystal (Si) |

7 | 78 | 1,414 | 3.4 | 160 | 0.1~100 | 11N | N P |

| Columnar Crystal (Si) |

7 | 85 | 1,414 | 3.3 | 163 | 0.001~10 | 6N | P |

Available Sizes and Machining Capability

| Availability | Sizes(mm) | Machining Capability | Sizes(mm) |

|---|---|---|---|

| Plate | 500×800×50(columnar crystal Si only) | Hole diameter | Φ0.03 or more |

| Rod | Φ100×400(columnar crystal Si only) | Hole depth | 20D(if less thanΦ1.5)、400(if less thanΦ1.5) |

| Groove width | Width ~0.05 | Max. hole number | 5,000 |

| Max. Groove(pocket) depth | 100 | Thread size | M3 or more (Installation of helical coil inserts required) |

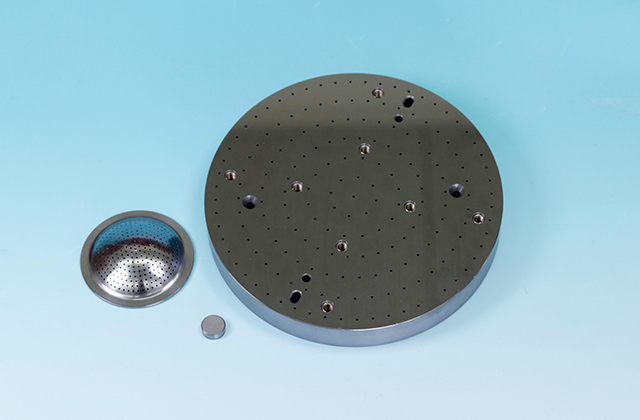

Silicon Custom Machined Parts

Top Seiko Co., Ltd.

〒526-0105

1197-4, Hosoe-cho, Nagahama City,

Shiga Pref.,526-0105 Japan

[ Access Map ]