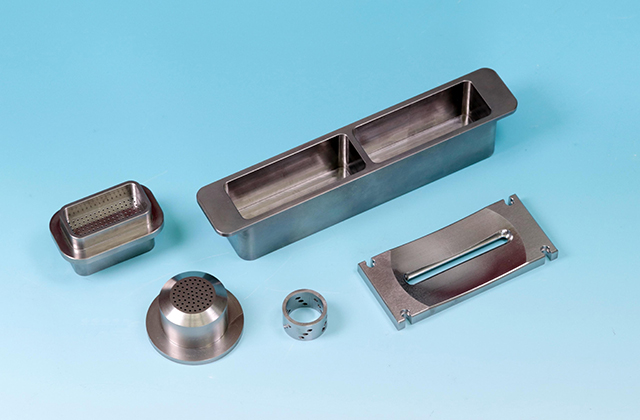

Tantalum (Ta) – Custom Machined Parts

Tantalum is characterized by its high density, extremely high melting point (3,017°C), and excellent corrosion resistance. Being extraordinarily resistant to heat, it is classified as a refractory metal.

In contrast to other refractory metals such as tungsten and molybdenum, production of tantalum often involves melting operation just like most industrial metals and alloys, which produces less material defects. Also, tantalum has good ductility and machinability compared to other refractory metals.

Despite all of these advantages of tantalum, however, applications are often limited to small parts/components due to its high cost.

Tantalum Properties

| Property(Unit) | Purity (%) |

Bulk Density (g/㎤) |

Vickers Hardness (GPa) |

Young’s Modulus (GPa) |

Malleability (%) |

Melting Point (℃) |

Recrystallization Temperature (℃) |

Coefficient of Thermal Expansion (×10-⁶/℃) |

Thermal Conductivity (W/(m・K)) |

Volume Resistivity (Ω・㎝) |

|---|---|---|---|---|---|---|---|---|---|---|

| Chemical Formula | ||||||||||

| Ta | 99.9~ | 16.6 | 0.69~1.2 | 185 | 20 | 3,017 | 900~1,450 | 6.3 (RT~600℃) |

54 (RT) |

13.1 ×10-⁶ |

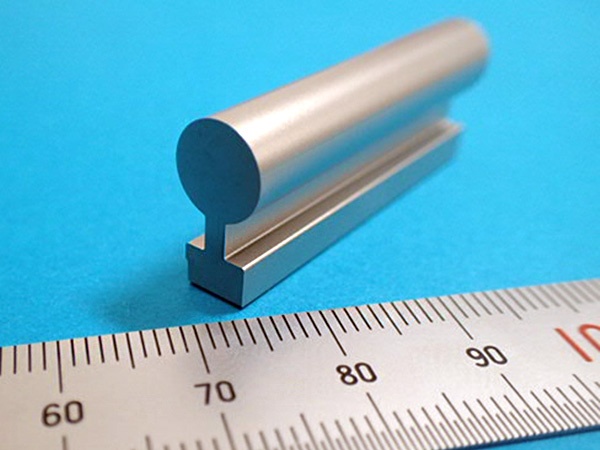

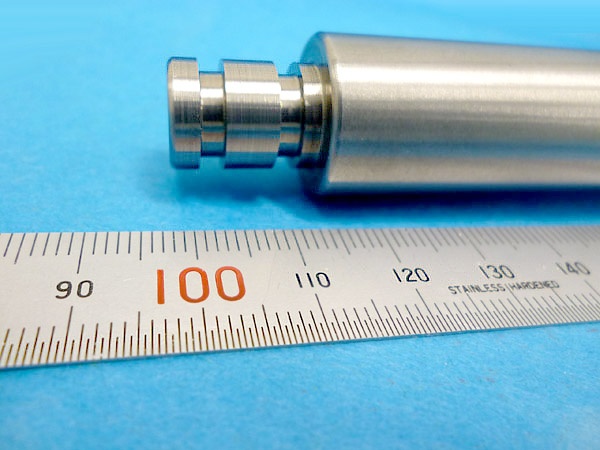

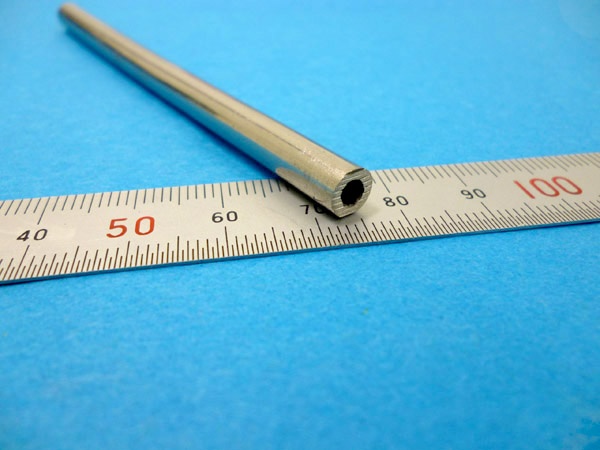

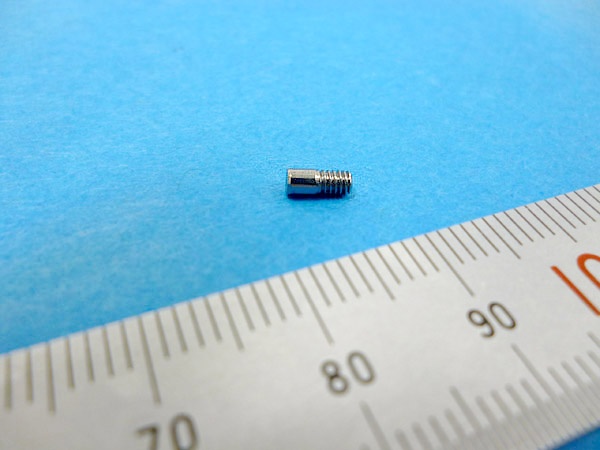

Available Sizes and Machining Capability

| Availability | Sizes(mm) | Machining Capability | Sizes(mm) |

|---|---|---|---|

| Plate | 100×100×10 | Hole diameter | Φ0.05 or more |

| Rod | Φ20×200 | Hole depth | 300 or less |

| Groove width | 0.05 or more | Max. hole number | 1,000 |

| Max. Groove(pocket) depth | 30 | Thread size | M1 or more |

Tantalum Custom Machined Parts

Top Seiko Co., Ltd.

〒526-0105

1197-4, Hosoe-cho, Nagahama City,

Shiga Pref.,526-0105 Japan

[ Access Map ]