Precision Machining of Zirconia: Challenges and Solutions

2023.04.20

When you hear the word zirconia, dental applications might be the first thing that comes to mind. While zirconia (zirconium dioxide, ZrO₂) is widely used in dental restorations due to its strength and biocompatibility, its unique properties make it an ideal material across a wide range of high-tech industries, including aerospace, electronics, and medical devices.

Why Choose Zirconia?

Zirconia is renowned for its:

-

Exceptional strength and fracture toughness – up to 1,200 MPa, making it nearly 10 times stronger than conventional ceramics like alumina.

-

Superior wear resistance – ideal for high-friction environments such as cutting tools and implants.

-

Thermal stability – it withstands extreme temperatures without degrading, making it suitable for components in gas turbines, furnaces, and other high-temperature environments.

-

Biocompatibility and aesthetics – especially valuable in medical and dental applications.

These properties make zirconia one of the most versatile and high-performance technical ceramics on the market today.

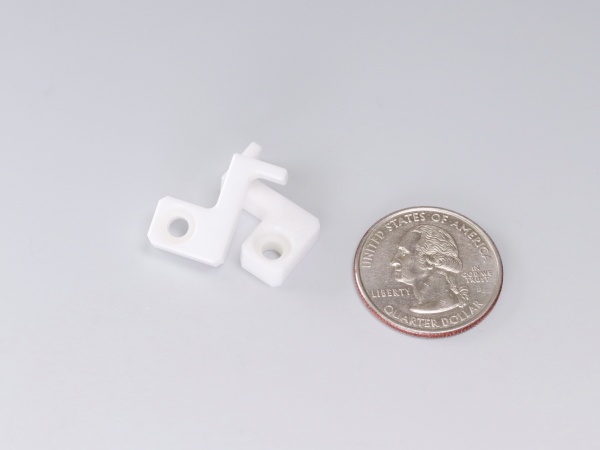

Custom-shaped zirconia clamping component used in various manufacturing devices. 5 x 10 x 3 mm(T)

The Challenge: Precision Machining of Zirconia

Despite its many advantages, zirconia presents challenges in manufacturing due to its hardness and brittleness. Traditional machining methods like milling or drilling can lead to cracking or surface damage. To achieve high-precision results, specialized tools—such as diamond-coated tools—and advanced machining techniques are essential.

How Top Seiko Delivers Superior Zirconia Machining

At Top Seiko, we specialize in precision machining of advanced ceramics like zirconia. With cutting-edge equipment and a team of experienced engineers, we are able to deliver high-quality, custom components that meet the most demanding specifications. Whether you need prototypes or production volumes, we ensure precision, consistency, and reliability every time.

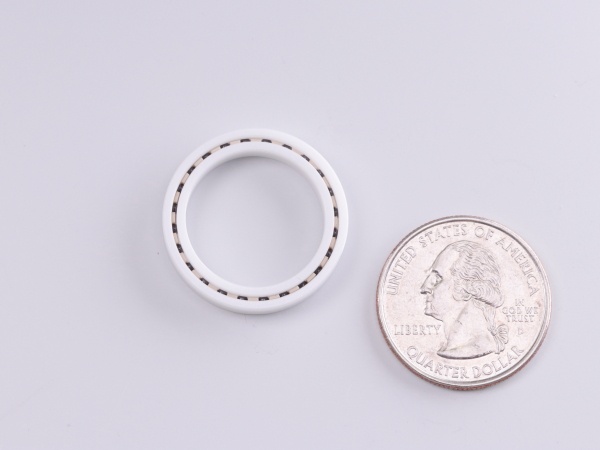

Custom-designed ceramic bearing example. φ22.00xφ18.00

Partner with Top Seiko for Your Zirconia Projects

Zirconia is an outstanding material for high-performance applications, but it demands expert handling during manufacturing.

By partnering with Top Seiko, you gain access to specialized knowledge and advanced capabilities that will give your projects a competitive edge.

📩 Contact us today to learn more about our zirconia machining services and how we can support your next project.