Si-SiC diffusion bonding

| Produkt | Si-SiC material Diffusion bonding |

|---|---|

| Material | Si-SiC |

| Verfahren | Difussion bonding of a Si-SiC plate |

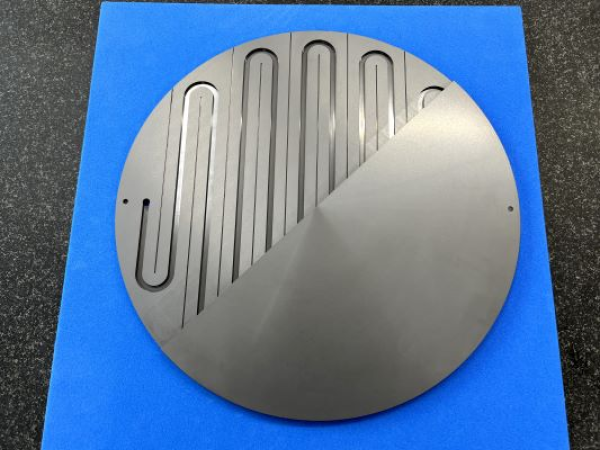

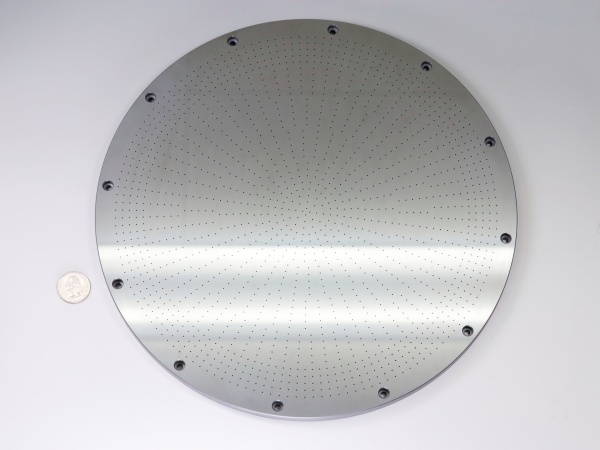

| Größe | φ300 |

| Anmeldung | The diffusion bonding process we are developing can join members of different shapes without using intermediate materials. The appeal of this technology is that it can create shapes that are difficult to machine while maintaining the characteristics of the base material. This technology makes it possible to combine unique characteristics into a single structure by (1) deep hole shape, (2) internal flow channels, (3) addition or division of flow channels, etc., although the size is the same as that of conventional parts. This technology contributes to the achievement of complex and multifunctional shapes required for various applications. |

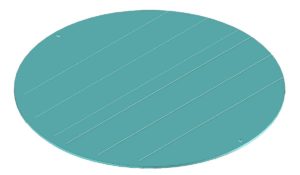

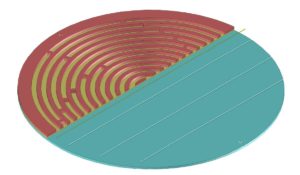

| Beschreibung | ■ Image of shape before joining * Outside size: φ300 ① Grooved layer Machining a groove as a side hole (290mm at the deepest point) (Assumed to be 290mm at the deepest point)

② Cover layer Cover of the groove layer

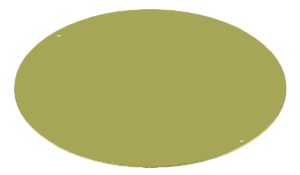

③ Slit layer Slit to be used as a groove after bonding

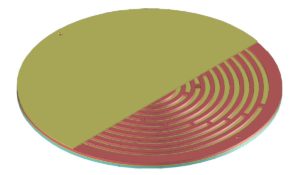

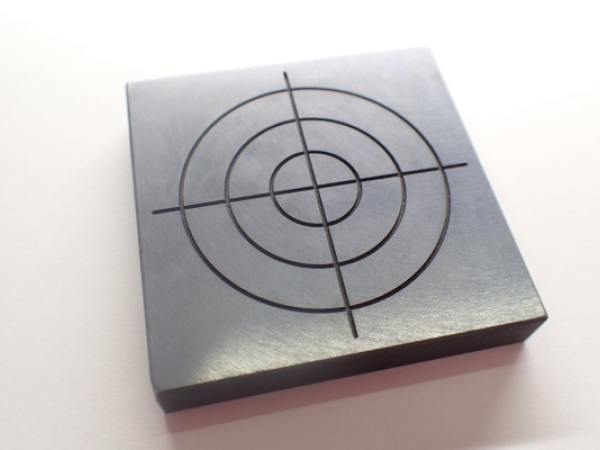

■ Illustration of shape after bonding *Some cross sections are shown to reveal the deep hole.

■ External image of actual sample ・Groove Additional work is possible after joining

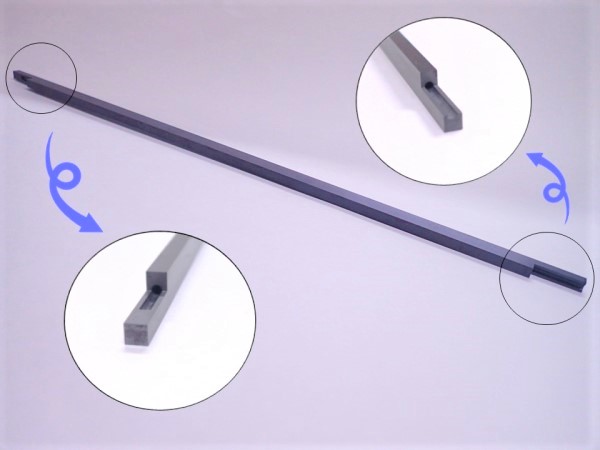

・Side hole * A rod of 0.65 mm dia. x 300 mm in length is inserted. (Same length as the image above) *Possible to create a long hole

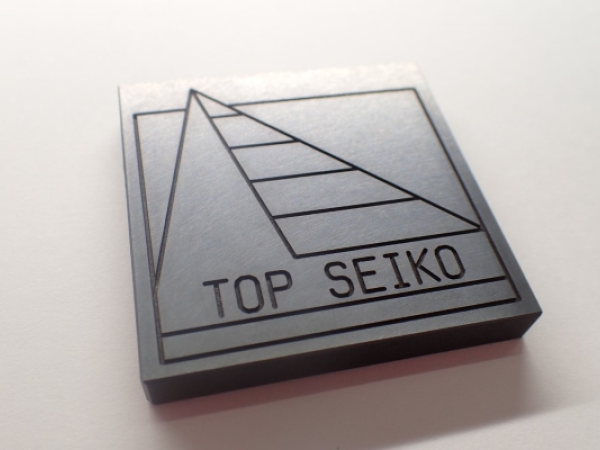

■ Final developed product illustration In addition, by joining the lid material, the flow path can be freely formed.

|