Deposition and Ion Implantation Processes

2024.09.07Combining Deposition and Ion Implantation Techniques

Introduction:

Deposition Techniques

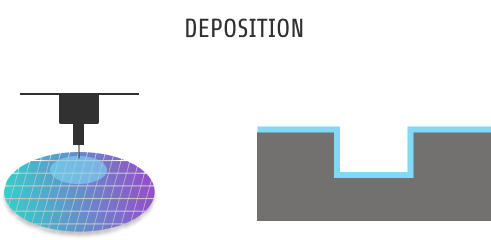

Several deposition methods are used, including Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD).

In PVD, a solid material vaporizes and then condenses onto the substrate, forming a thin film. One common PVD method is sputtering. During sputtering, high-energy ions bombard a target material. This action knocks atoms off the target, and these atoms then deposit onto the substrate, creating a thin film.

On the other hand, CVD involves introducing a precursor gas into a reaction chamber. The gas undergoes chemical reactions inside the chamber, which results in the deposition of a thin film onto the substrate.

Processes Overview:

Deposition is a crucial process in semiconductor manufacturing. This technique involves applying thin layers of material onto a substrate. These layers form essential components in semiconductor devices.

Key Layers Created:

-

Conductive Layers: These layers create electrical pathways. They allow current to flow between different parts of the device and establish connections within integrated circuits.

-

Insulating Layers: These layers prevent electrical interference. They also avoid short circuits by isolating conductive layers. Consequently, this isolation helps maintain reliable device performance.

-

Semiconducting Layers: These layers enable the device to perform critical electronic operations. For example, they handle switching and amplification tasks.

In summary, the deposition process applies these layers with precision and uniformity. This accuracy is crucial for producing high-quality semiconductor devices that meet strict performance standards.

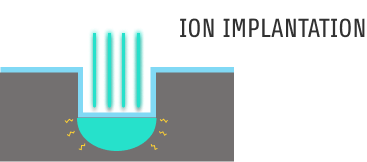

Ion implantation is a key technique for modifying the electrical properties of semiconductor materials. This process introduces impurity ions to change the material’s characteristics.

Process Overview:

-

Ion Acceleration: We first accelerate ions to high energies. Next, we direct these ions towards the semiconductor wafer. This high-energy acceleration allows ions to penetrate the material effectively.

-

Ion Penetration and Embedding: The ions then embed themselves into the crystal lattice of the semiconductor. This embedding alters the material’s electrical properties.

Overall, this technique is essential for fabricating integrated circuits and other semiconductor devices. It ensures the creation of precise doping profiles. These profiles are necessary for forming functional electronic components, such as transistors and diodes.

Chosing the right partner:

The quality of deposition and ion implantation processes has a significant impact on the performance of your electronic components.

To ensure optimal results, it is essential to work with a reliable and experienced partner.

Top Seiko specializes in providing precision manufacturing services and high-quality components that support these advanced processes.

By choosing Top Seiko, you benefit from our expertise in delivering components that meet the stringent requirements of semiconductor production. Our focus is on ensuring that your technology projects succeed through precise and efficient manufacturing.

Conclusion:

In summary, deposition and ion implantation are essential processes for producing advanced electronic devices.

By leveraging Top Seiko’s expertise, you can achieve outstanding results for your manufacturing needs.

Contact us today to learn how we can support you in reaching your technological goals.

Further Reading and Resources:

For more detailed information on high-performance materials and their applications, visit the Top Seiko News Blog.