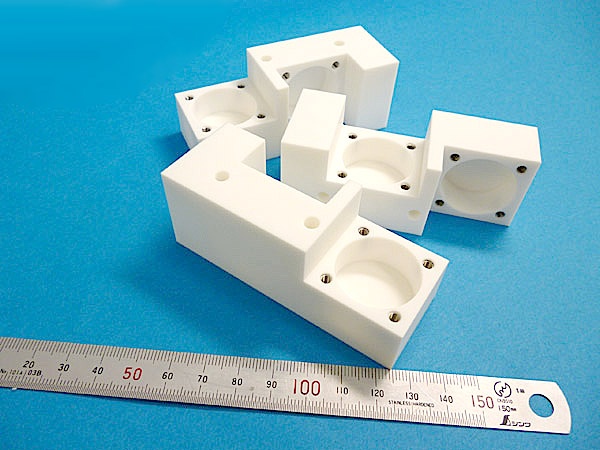

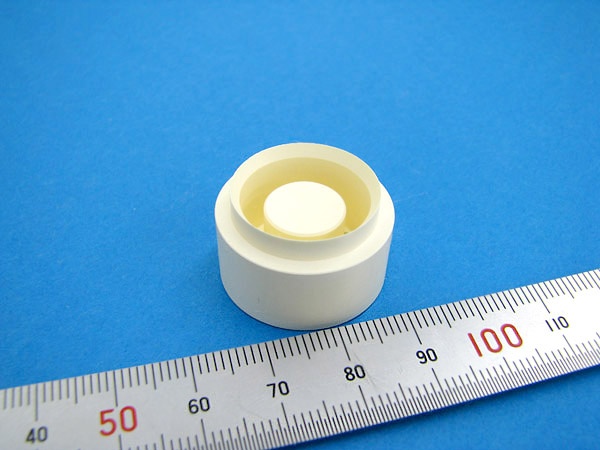

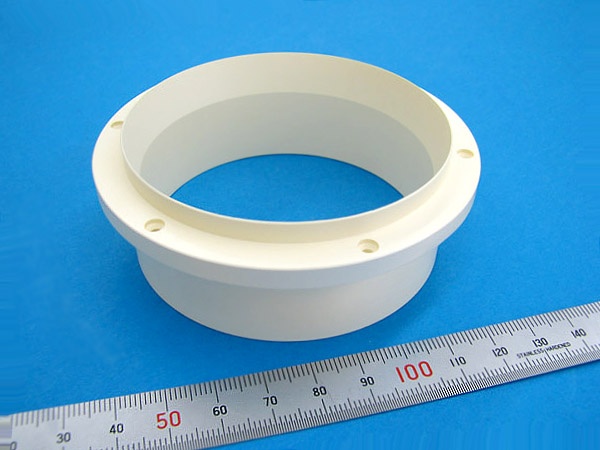

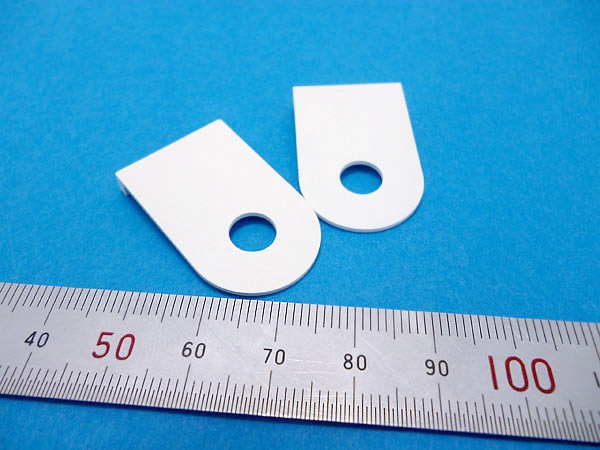

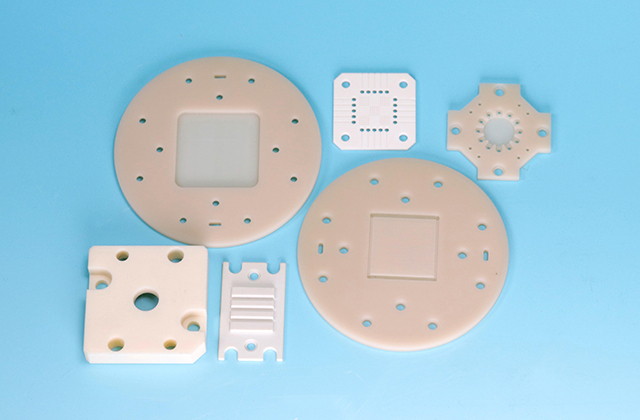

Machinable Ceramics – Custom Machined Parts

There are a number of different machinable ceramics with varying properties produced by several material manufacturers. However, unlike engineering ceramics, all machinable ceramics can be machined into complex and precision parts with extremely small features using standard metal working/cutting tools.

As machinable ceramics can be quickly and inexpensively machined, they are often used to make precision parts for rapid prototypes. If you are not familiar with these materials, we will help you select a machinable ceramic with the right properties for your application. Take advantage of Top Seiko’s comprehensive precision machining service including material selection assistance and material sourcing!

Property Comparison Table of Machinable Ceramics

| Property (Unit) |

Composition | Content Rate(%) | Vickers Hardness (GPa) |

Flexural Strengt (MPa) |

Max Use Temperature (℃) (oxidizing atmosphere) |

Max Use Temperature (vacuum condition)(℃) |

Coefficient of Thermal Expansion (×10-⁶/℃) |

Thermal Conductivity (W/(m・K)) |

Thermal Shock Resistance(℃) | Dielectric Strength (kV/mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| Material | ||||||||||

| Macerite-S | Fluorian phlogopite | - | 2.2 | 110 | 1,000 | 1,200 | 9.3 RT~400℃ |

1.6 | 150 | >10 |

| Photoveel | Fluorian phlogopite ZrO₂ |

- | 2.2 | 150 | 1,000 | 1,000 | 7.8 RT~800℃ |

1.5 | 150 | 20 |

| Macor | Fluorian phlogopite borosilicate glass |

55 - 45 |

2.2 | >94 | 1,000 | 800 | 9.3 RT~300℃ |

1.4 | 200 | 40 |

| N-1 | BN | >99 | Shore Hardness12(HS) | 30 | 950 | 2,000 | -1.4 RT→1000℃ |

63 | - | 25 |

| BA-2000 | AlN BN |

80 20 |

Shore Hardness40(HS) | 120 | 950 | 1,950 | 5.4 | 95 | - | 15 |

| SBN30 | Si₃N₄ BN |

30 70 |

Shore Hardness48(HS) | 140 | 950 | 1,500 | 2.0 | 33 | - | 27 |

| SBN50 | Si₃N₄ | 50 50 |

Shore Hardness69(HS) | 270 | 950 | 1,500 | 2.6 | 47 | - | 36 |

| Shapal Hi M-Soft | AlN BN |

- | 3.8 | 300 | 1,000 | 1,900 | 4.4 | 90 | 400 | 40 |

Machinable Ceramics – Key Properties & Popular Applications

| Key Properties | Applications | |

|---|---|---|

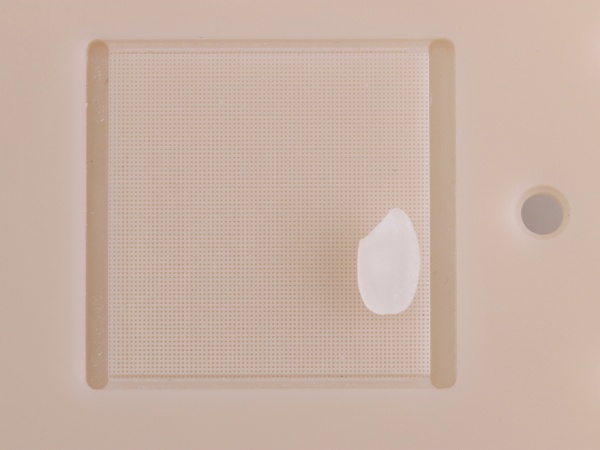

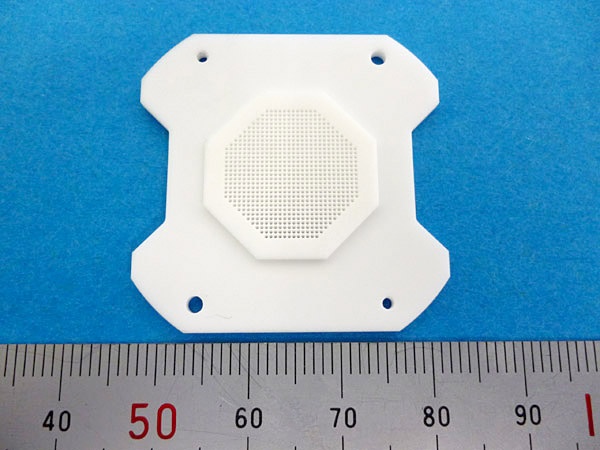

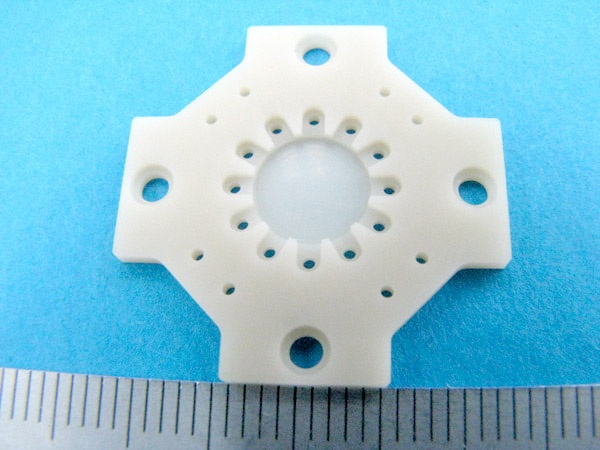

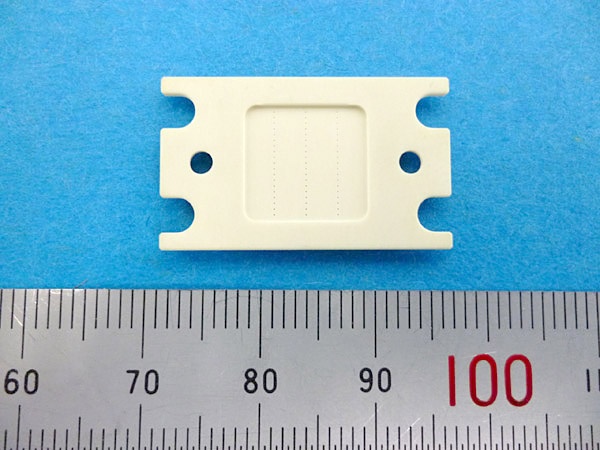

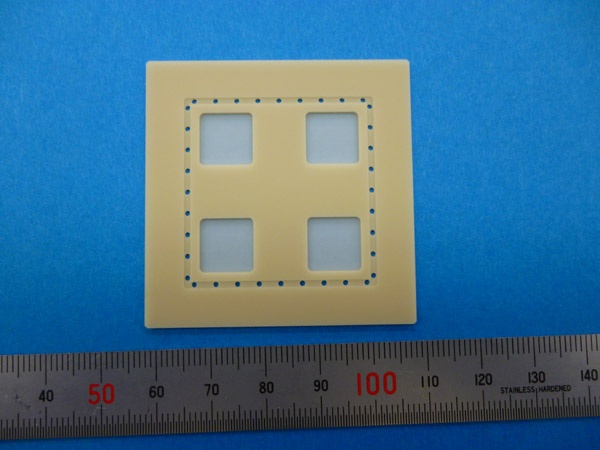

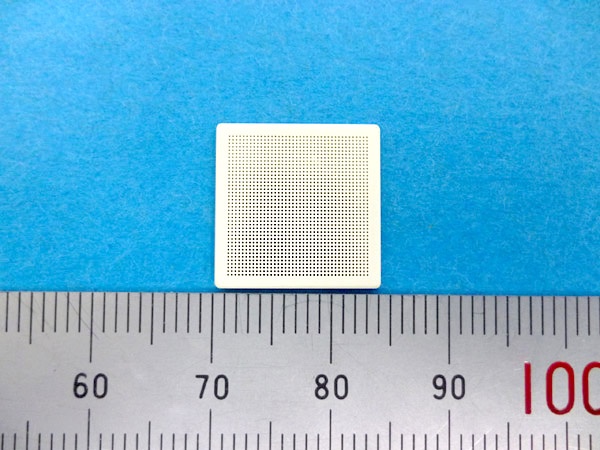

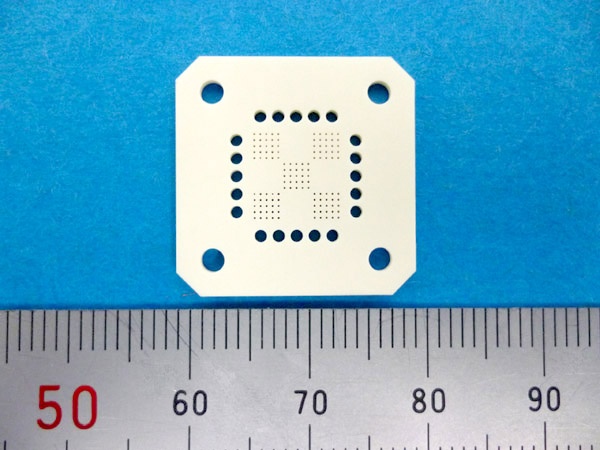

| Easily Machinable | Machinable ceramics are ideal for micromachining small features and holes. |

■Fixtures and parts used in high temperature environments ■Fixture parts requiring the CTE closely matches that of Silicon ■Parts subject to rapid heating and cooling ■High temperature electrical insulators |

| High Hardness & Strength | The mechanical properties of machinable ceramics tend to be lower than those of engineering ceramics. However, fine-grained machinable ceramics are nearly as strong as alumina. | |

| Excellent Heat Resistance | Machinable ceramics with high BN, Si3N4 and/or AlN contents can withstand very high temperatures. | |

| Available in a wide range of CTEs |

Values of thermal expansion vary from negative to high depending on the machinable ceramic material. Shapal Hi-M soft and BA-2000 have thermal expansion coefficients similar to that of Silicon. |

|

| High Thermal Shock Resistance | Machinable ceramics with high BN, Si3N4 and/or AlN contents have high thermal shock resistance. | |

| High Dielectric Strength | Some machinable ceramics including Macor and Boron Nitride machinable ceramic have superior high dielectric strength. | |

Note: Machinable Ceramics in general are relatively high cost materials, and their applications are usually limited to small parts/ components.

Available Sizes and Machining Capability

| Availability | Sizes(mm) | Machining Capability | Sizes(mm) |

|---|---|---|---|

| Plate | 300 x 300 x 50 thickness | Hole diameter | Φ0.05~ |

| Rod | Φ50×300 | Hole depth | 300 or less |

| Groove width | 0.05 or more | Max. hole number | 10,000 |

| Max. Groove(pocket) depth | 50 | Thread size | M1.2 or more |

Note: Available sizes vary depending on each material.

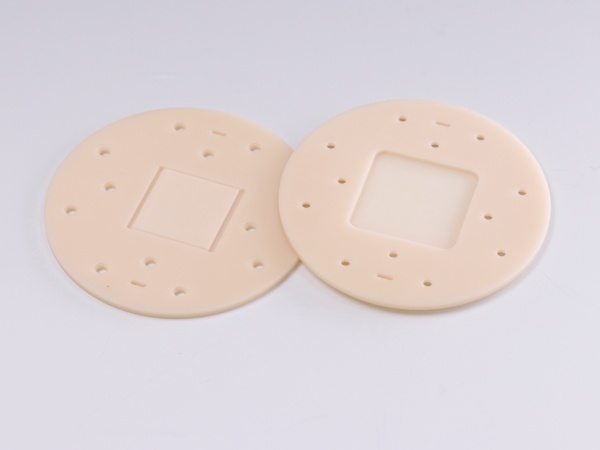

Machinable Ceramics Custom Machined Parts

Ceramics List

-

- Alumina(Al₂O₃)

-

Excellent electrical insulation properties , High temperature resistance , Plasma resistance , High hardness , Wear resistance

-

- Aluminum nitride(AlN)

-

High thermal conductivity , High temperature resistance , Low thermal expansion , Excellent electrical insulation properties , Plasma resistant , Corrosion resistant

-

- Zirconia(ZrO2)

-

High fracture toughness , Low thermal conductivity , Wear resistant

-

- Silicon carbide(SiC)

-

High hardness , High thermal conductivity , High mechanical strength , Corrosion resistant

-

- Silicon Nitride (Si3N4)

-

High fracture toughness , Low thermal expansion , Wear resistant , Good thermal shock resistance

-

- Machinable Ceramics

-

Excellent electrical insulation properties , High machinability , High temperature resistance

Top Seiko Co., Ltd.

〒526-0105

1197-4, Hosoe-cho, Nagahama City,

Shiga Pref.,526-0105 Japan

[ Access Map ]