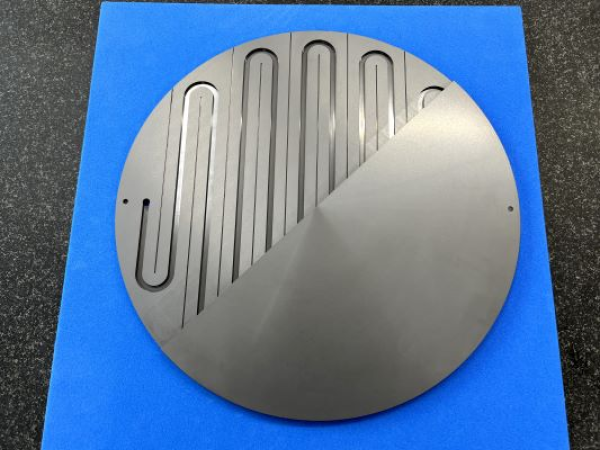

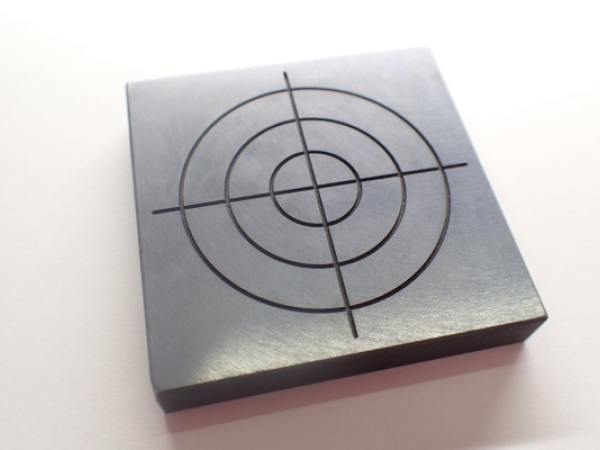

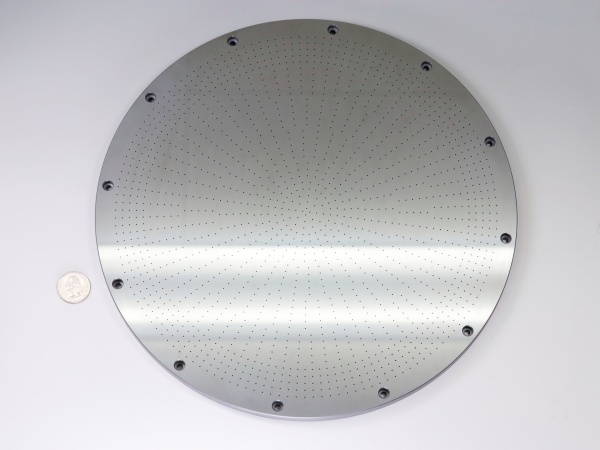

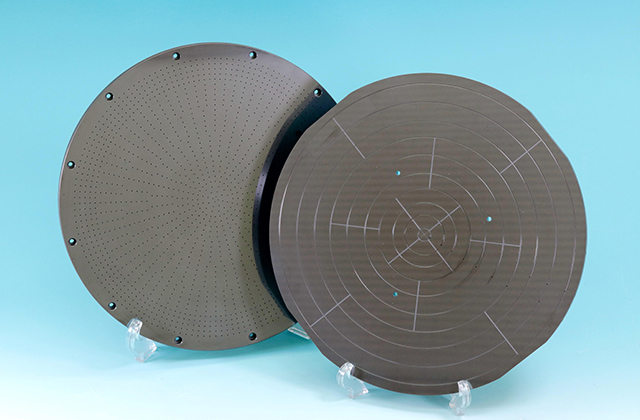

Composite Materials – Custom Machined Parts

Top Seiko has extensive experience in precision machining of Metal Matrix Composites (MMCs) based on Silicon – Silicon Carbide. MMCs are available in large sizes and can be more cost-effective than silicon carbide.

We also handle precision machining of Ceramic Matrix Composites (CMCs). Due to non-disclosure requirements, we cannot introduce further information.

Property Comparison Table of Composite Materials

| Property (Unit) |

Composition | Content Rate (vol%) |

Vickers Hardness (GPa) |

Flexural Strength (GPa) |

Fracture Toughness (MPam¹/²) |

Max Use Temperature (℃) |

Coefficient of Thermal Expansion (×10-⁶/℃) |

Thermal Conductivity (W/(m・K)) |

Volume Resistivity (μΩ・㎝) |

|---|---|---|---|---|---|---|---|---|---|

| Material | |||||||||

| SS501 | SiC Si |

50 50 |

- | 300 | 3 | 1,200 (for reference only) |

2.8 (RT~200℃) |

175 | 2×10-2 |

| SS701 | SiC Si |

70 30 |

- | 300 | 3 | 1,200 (for reference only) |

3.0 (RT~200℃) |

190 | 2×10-2 |

| PARUCOCERAM SI | SiC Si |

82 18 |

- | 250 | 3 | 1,350 (for reference only) |

3.4 (RT~700℃) |

220 | 10-1 (for reference only) |

| SA701 | SiC Al |

70 30 |

- | 340 | 8 | - | 7.0 (RT~200℃) |

160 | 10-5 |

| High Purity Sintered SiC | SiC | 99 | 24 | 500 | 3 | - | 2.9 (RT) |

150 | >10⁶ |

Composite Materials – Key Properties & Popular Applications

| Key Properties | Applications | |

|---|---|---|

| Available in Large Size | MMCs are available in larger sizes than silicon carbide. |

■Machinery components ■Jigs / fixtures ■Parts requiring minimum strength-to-weight ratios ■Parts subject to high temperatures or heavy loads ■Precision & intricate parts ■Heat transfer components ■Heat sinks & heat spreaders ■Vacuum equipment parts ■Parts requiring fine surface finishing by polishing ■Cost-effective alternative to silicon carbide |

| Good Machinability |

Due to their good machinability, MMCs are easier to produce intricate and high precision parts than SiC. This makes MMCs popular materials to replace SiC and conventional materials in many applications where stiffness and strength as well as weight reduction are needed. Our extensive experience in precision machining of MMCs enables us to optimize machining conditions to provide our customers the best quality parts at the lowest possible prices. |

|

| High- Temperature Capability | MMCs can retain high strength at elevated temperatures. | |

| Low Thermal Expansion | MMCs have low thermal expansion, and can maintain | |

| Warp- & Distortion -Proof | dimensional stability when subjected to varying temperature conditions. | And other structural applications. |

| High Thermal Conductivity | Due to their excellent heat-conducting property, MMCs can effectively transfer (dissipate) heat. | |

| Less Material Defect | MMCs which we handle are produced by metal (E.g. Si) impregnation method which enables low defect rate. | |

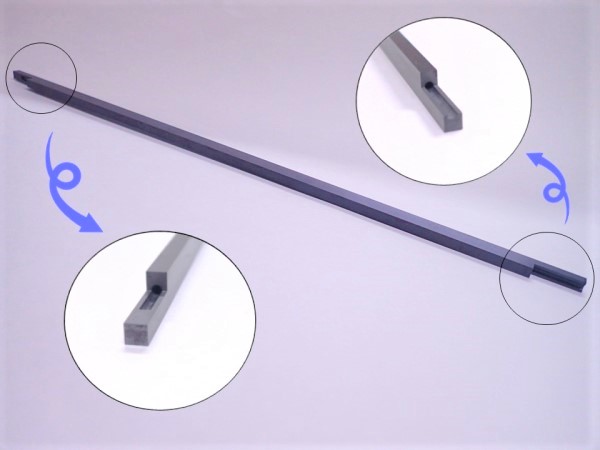

Available Sizes and Machining Capability

| Availability | Sizes(mm) | Machining Capability | Sizes(mm) |

|---|---|---|---|

| Plate | 600×800 | Hole diameter | Φ0.05~ |

| Rod | Φ50×400 | Hole depth | ~300 |

| Groove width | 0.05 or more | Max. hole number | 1,000 |

| Max. Groove(pocket) depth | 50 | Thread size | M2 or more |

Composite Materials – Custom Machined Parts

Top Seiko Co., Ltd.

〒526-0105

1197-4, Hosoe-cho, Nagahama City,

Shiga Pref.,526-0105 Japan

[ Access Map ]