Single Crystal Sapphire (Al2O3) – Custom Machined Parts

Single crystal sapphire has a unique combination of excellent mechanical, thermal, chemical and optical properties. It retains its high strength at high temperatures. It is also chemically inert to common acids and alkali even at elevated temperatures. Combined with its wide transmission range from ultraviolet to infrared, it is the ideal material for optical components used in hostile environments.

Second only to diamond in hardness, sapphire is extremely durable and scratch & wear resistant. It is often used in making parts and components for hard wearing applications requiring high level of scratch resistance.

Property Comparison Table of Sapphire and Fused Silica

| Property (Unit) |

Purity (%) |

Structure | Vickers Hardness (GPa) |

Flexural Strength (GPa) |

Young’s Modulus (GPa) |

Coefficient of Thermal Expansion (×10-⁶/ ℃) |

Thermal Conductivity (W/(m・K)) |

Volume Resistivity (Ω・㎝) |

Chemical Resistance |

|---|---|---|---|---|---|---|---|---|---|

| Material & Chemical Formula | |||||||||

| Sapphire (Al₂O₃) |

99.99 | Single Crystal Form | 23 | 700 | 470 | 7.2 (Parallel to C-Axis) |

42 | >10¹⁴ | Excellent |

| Fused Silica (SiO₂) |

99.99 | Non-Crystalline Form | 9 | 94 | 74 | 0.64 | 1 | 5×10¹⁶ | Excellent |

Available Sizes and Machining Capability

| Availability | Sizes(mm) | Machining Capability | Sizes(mm) |

|---|---|---|---|

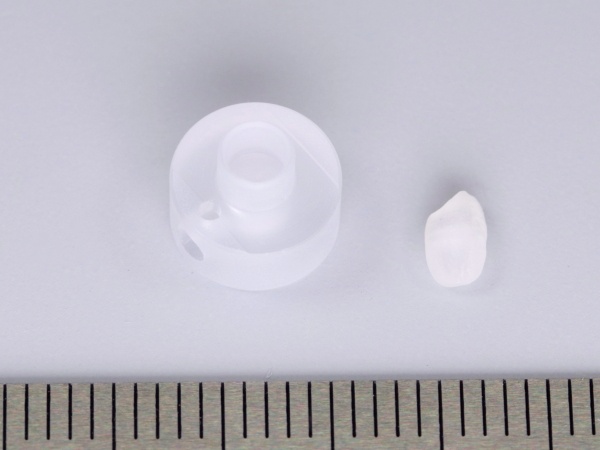

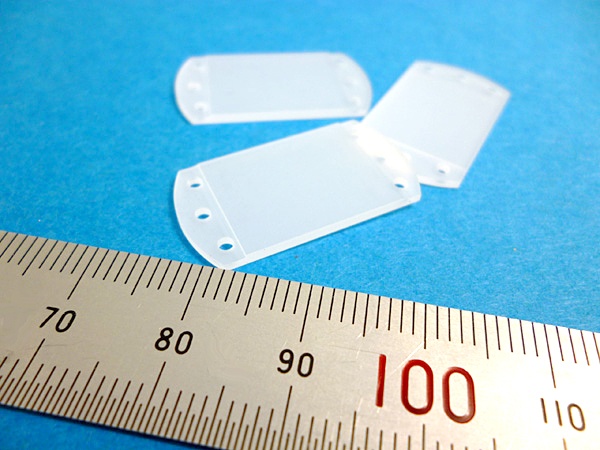

| Plate | Φ150×t10 | Hole diameter | Φ0.2 or more |

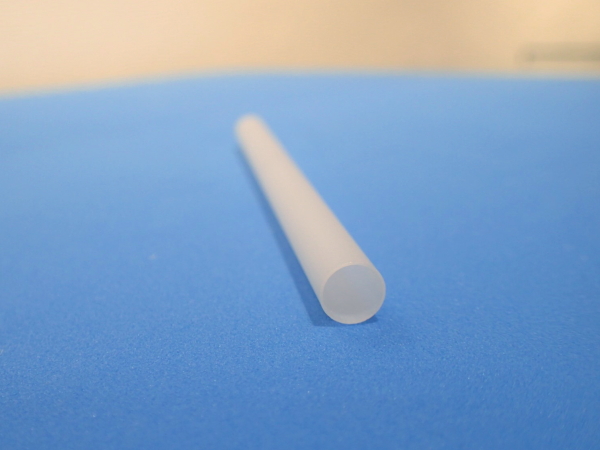

| Rod | Φ50×200 | Hole depth | 20D(~Φ1.5)、300(Φ1.5~) |

| Groove width | 0.2 or more | Max. hole number | 300 |

| Max. Groove(pocket) depth | 20 | Thread size | M2 or more |

Sapphire Custom Machined Parts

Top Seiko Co., Ltd.

〒526-0105

1197-4, Hosoe-cho, Nagahama City,

Shiga Pref.,526-0105 Japan

[ Access Map ]