Tungsten (W) – Custom Machined Parts

Tungsten has excellent high-temperature properties including the highest melting point of all metals and the lowest thermal expansion of all pure metals, and is used in many high-temperature applications. Also, due to its high density comparable to that of gold, it exhibits superior radiation shielding performance.

Tungsten is an extremely hard and crack-sensitive metal which is brittle at room temperature. Its extreme hardness causes excessive tool wear, and its brittleness makes the material prone to chipping and cracking during and after machining. Therefore, it requires special handling and machining techniques.

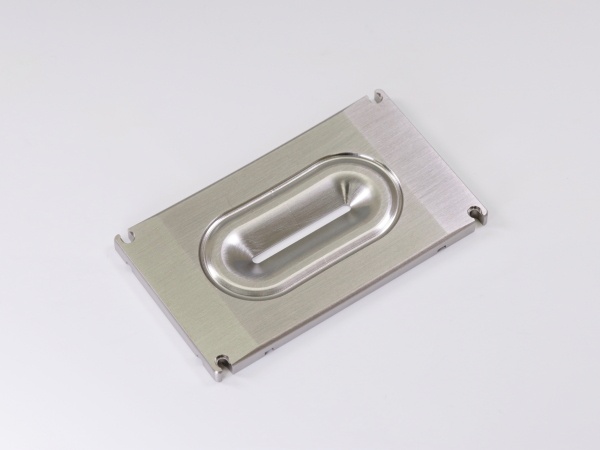

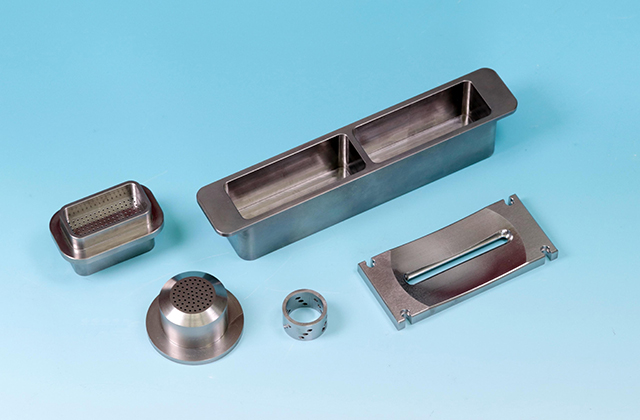

Top Seiko has provided custom-machined tungsten parts to customers in a wide range of industries. Complex and precision machining of tungsten is indeed our specialty. We stock tungsten in various sizes and thickness to shorten lead times for customers with urgent needs.

Tungsten Properties

| Property(Unit) | Purity (%) |

Bulk Density (g/㎤) |

Vickers Hardness (GPa) |

Young’s Modulus (GPa) |

Melting Point (℃) |

Recrystallization Temperature (℃) |

Coefficient of Thermal Expansion (×10-⁶/℃) |

Thermal Conductivity (W/(m・K)) |

Volume Resistivity(Ω・㎝) |

|---|---|---|---|---|---|---|---|---|---|

| Chemical Formula | |||||||||

| W | 99.95~ | 19.3 | 4.2 | 403 | 3,422 | 1,150~1,350 | 4.5 | 168 | 5.5×10-6 |

Tungsten – Key Properties & Popular Applications

| Key Properties | Applications | |

|---|---|---|

|

■High temperature resistance ■Low thermal expansion ■High thermal conductivity |

Having a melting point of 3422 °C, tungsten can easily withstand even the most intense heat. Combined with its extremely low thermal expansion, it resists distortion and warping at elevated temperatures. In fact, it has a coefficient of thermal expansion close to those of alumina and borosilicate glasses. Its high thermal conductivity coupled with its high melting point makes tungsten ideal material for efficient and quick heat transfer even at high temperatures. |

■Parts subject to extremely high temperatures ■Heat transfer components used at high temperatures ■Heat sinks & Heat spreaders ■Terminal pins ■Electrodes ■Radiation shielding parts ■Weight parts & Balance weights |

| High Density & High Radiation Shielding Performance | With its density of 19.3/cm3, tungsten is the heaviest engineering material. Its high density makes this material ideal for a variety of low volume/high weight applications. This also means that it is an excellent radiation shielding material. | |

| Excellent Corrosion Resistance | Tungsten has good resistance to most acids and bases. | |

Available Sizes and Machining Capability

| Availability | Sizes(mm) | Machining Capability | Sizes(mm) |

|---|---|---|---|

| Plate | 400×600×30 | Hole diameter | Φ0.1 or more |

| Rod | Φ100×300 | Hole depth | 300 or less |

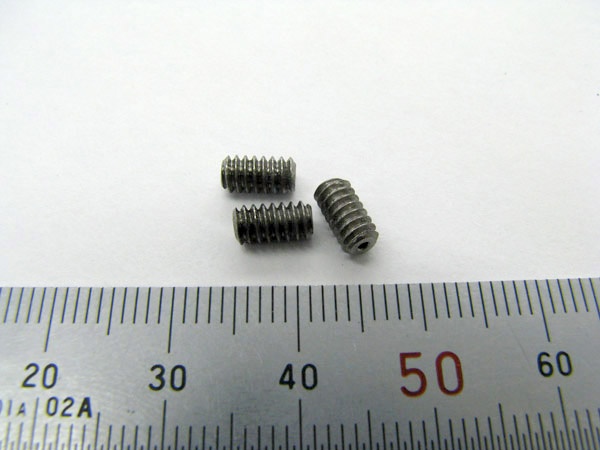

| Thread size | M2 or more | Max. hole number | 300 |

| Max. Groove(pocket) depth | 100 | Thread size | M2 or more |

Top Seiko Co., Ltd.

〒526-0105

1197-4, Hosoe-cho, Nagahama City,

Shiga Pref.,526-0105 Japan

[ Access Map ]