Why Precision Machining Costs More – and Why It’s Worth It

2025.06.06Precision machining is about more than just cutting parts.

It’s about delivering reliable, high-performance components that meet exacting standards.

At Top Seiko, we specialize in ultra-precision machining—and we’re often asked why it costs more than standard solutions.

Here’s what makes the difference.

Complex Geometries Require Expertise

Many precision components feature tight tolerances and intricate shapes.

These aren’t simple to produce. Each job requires advanced programming, complex setups, and careful attention to detail.

As a result, even small design changes can lead to new challenges in manufacturing.

Custom Tools Make a Big Impact

Off-the-shelf tools don’t always work.

In fact, many of our parts require tools and fixtures designed specifically for the material and geometry involved.

This means slightly longer preparation times—but also greater precision and repeatability.

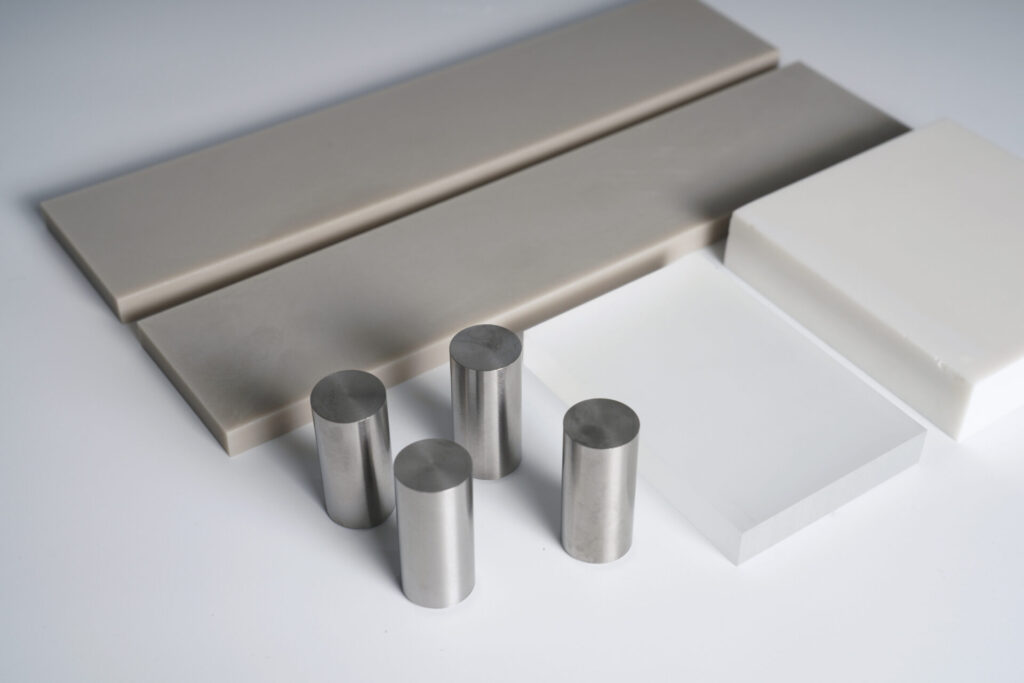

Material Quality Matters

We work with hard-to-machine materials, such as ceramics, quartz, and refractory metals.

These materials are essential to demanding industries, such as semiconductors and aerospace.

However, they are also costly, brittle, and sensitive to stress.

Without the right approach, the risk of failure increases dramatically.

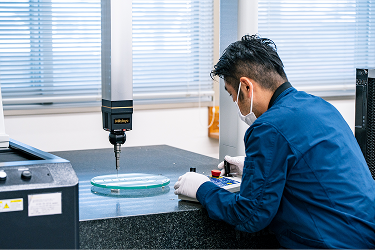

Quality Is Built In—From Start to Finish

Before machining begins, we verify the quality of every material batch.

After machining, each part is carefully inspected against customer specifications.

This full-cycle quality control ensures reliability and peace of mind.

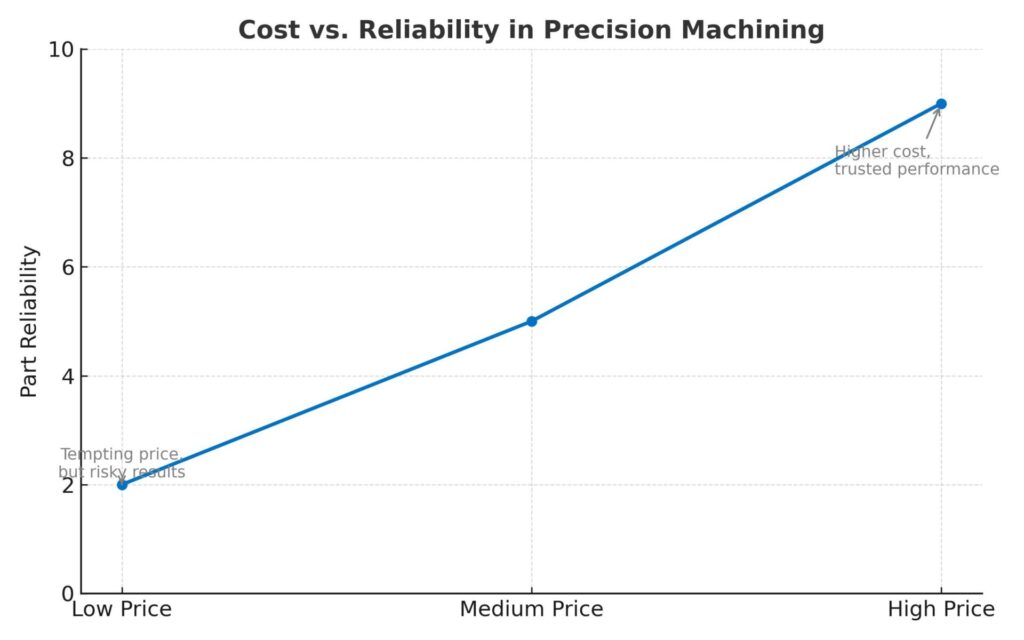

Cost vs. Reliability

It’s tempting to choose the lowest quote.

However, cheaper machining often results in poor material selection, inadequate tolerances, and inconsistent results.

In the end, that “savings” may cost more—in delays, failures, or rework.

Take a look at the chart below.

While price and quality don’t always rise in perfect sync, the trend is clear: achieving real precision requires a real investment.

We’ve seen clients come to us after experiencing failures from cheaper suppliers

—because fixing a problem is always more expensive than doing it right the first time.

Why Top Seiko?

– Over 20 years of experience

– Trusted by global leaders in semiconductor and advanced industries

– 90% of our revenue comes from mission-critical sectors, where failure is not an option

When performance matters, cost is not just a number—it’s a guarantee of reliability.

Want to learn more about how we approach complex machining challenges?

Let’s talk !