Tungsten : Properties, Uses, and Benefits

2024.12.16What is Tungsten?

Introduction

Tungsten, symbolized by W and with an atomic number of 74, stands out due to its exceptional characteristics. It is renowned for having the highest melting point of all elements and is celebrated for its density and hardness.

This article will explore the key properties of tungsten, examine its diverse applications, and highlight the benefits it offers across various industries. Additionally, comparative hardness tables will be linked to enhance understanding of tungsten’s position relative to other materials.

Properties of Tungsten:

Tungsten plays a vital role in several fields because of its key properties:

- High Melting Point

With a melting point of 3422°C (6192°F), tungsten holds the record for the highest melting point of any element.

Consequently, industries highly value it for applications involving extreme temperatures.

For instance, aerospace components and industrial processes depend on tungsten’s ability to withstand intense heat. - Density and Hardness

Tungsten has a density of 19.25 g/cm³, making it one of the heaviest metals. Its hardness, which ranks just behind carbon, further enhances its usefulness. Therefore, industries use tungsten extensively in heavy-duty applications such as mining and defense.

- Thermal and Electrical Conductivity

The metal’s excellent thermal and electrical conductivity makes it ideal for high-performance electronic and electrical components. Consequently, tungsten ensures efficient operation in demanding environments. - Corrosion Resistance

Tungsten resists corrosion and oxidation, especially at high temperatures. This resistance significantly enhances its durability. As a result, tungsten performs well in harsh conditions where other materials might fail.

To gain a better understanding of tungsten’s hardness in relation to other materials, refer to the following tables:

https://top-seiko.com/guide/graph/

Tungsten machined parts from Top Seiko

Additional examples of machined tungsten parts :

https://top-seiko.com/works/material-cat/tungsten/

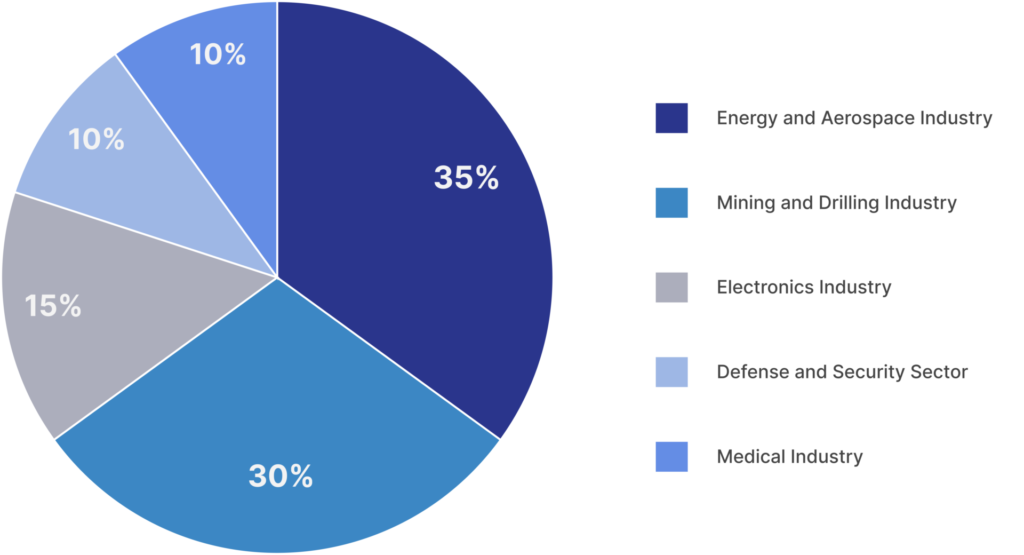

Estimated Distribution of Tungsten Usage Across Different Industries:

Tungsten proves critical in various industrial applications due to its high melting point, hardness, and density.

Moreover, tungsten’s unique properties not only contribute to its effectiveness in specific applications but also enhance its versatility across various industries.

As a result, its use spans multiple sectors, demonstrating its significance and broad applicability.

To grasp its significance, examining its distribution across different industries is helpful.

Benefits of Tungsten:

Tungsten’s unique physical and chemical properties make it valuable across various sectors.

Here, we highlight the key benefits that make tungsten a preferred choice in critical and demanding environments:

- Durability

Tungsten’s high melting point and hardness contribute to its durability.

This quality ensures longevity in applications where other materials might quickly degrade, reducing the need for frequent replacements. - Efficiency

Tungsten’s excellent thermal and electrical conductivity enhances the efficiency of electronic components and high-performance equipment. As a result, it ensures reliable operation in challenging conditions.

- Safety

Tungsten blocks radiation effectively, providing crucial safety benefits in medical and industrial settings.

Therefore, it protects both equipment and personnel from harmful radiation exposure.

- Wear Resistance

The hardness of tungsten makes it resistant to wear and abrasion.

This property is especially beneficial for cutting tools and drilling equipment, extending their lifespan and maintaining performance.

- High-Temperature Stability

Tungsten maintains its performance and structural integrity even at very high temperatures.

Consequently, it is essential for applications in aerospace and industrial processes where other materials might fail.

Conclusion:

Tungsten’s exceptional properties—high melting point, density, hardness, and resistance to corrosion—highlight its importance in high-tech and industrial applications. By exploring these attributes and using comparative hardness tables, you can better appreciate tungsten’s unique benefits.

Its role in advancing technology and industry continues to grow significantly.

If you need precision machining for Tungsten or other superhard materials, get in touch with us !

Discover how our specialized expertise can enhance your next project.

Further Reading and Resources

For more detailed information on other high-performance materials and their applications, visit the Top Seiko website : Top-Seiko.com