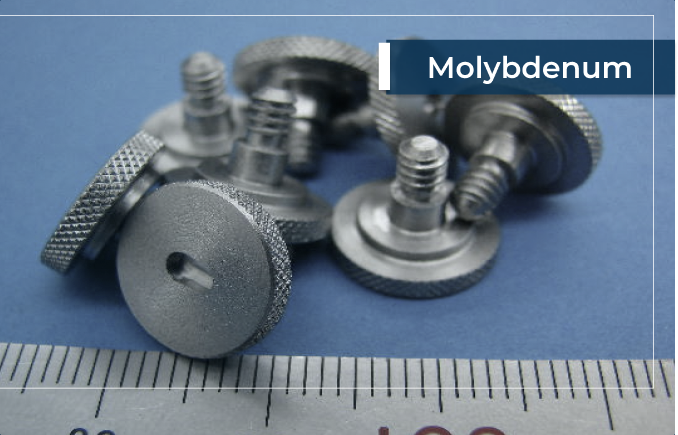

Custom Molybdenum Component Manufacturing

2024.12.03

At Top Seiko, we specialize in precision machining of advanced materials like molybdenum, meeting the exacting demands of industries worldwide.

Molybdenum’s unique properties make it an invaluable material for high-tech applications, and our expertise ensures your custom components meet the highest standards of quality and performance.

Why Molybdenum?

Molybdenum is an exceptional material for challenging environments, offering:

- Extreme Heat Resistance: Its melting point of 2623°C makes it ideal for high-temperature applications.

- High Strength and Stability: Maintains mechanical integrity even under heavy loads.

- Low Thermal Expansion: Ensures precision and minimal distortion under thermal stress.

- Corrosion Resistance: Withstands oxidation and chemical exposure, extending part life.

3D Molybdenum Wine Glass

Precision Machining for Your Needs

At Top Seiko, we understand that every project is unique. Whether you need molybdenum parts for aerospace, semiconductors, medical devices, or energy applications, our tailored machining services deliver:

- Exacting Precision: Achieving tight tolerances with micrometer accuracy.

- Complex Designs: Enabling intricate geometries and detailed features.

- Consistent Quality: Meeting strict specifications with every component.

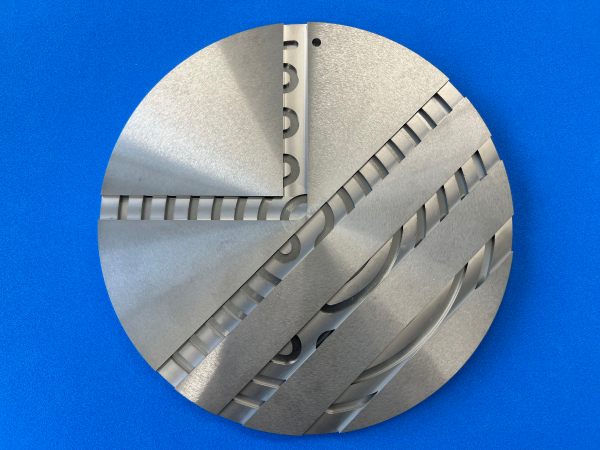

Innovative Techniques for Molybdenum

We combine advanced technologies with decades of experience to machine molybdenum with precision:

- CNC Machining: High-speed, high-accuracy tools for custom parts.

- EDM (Electrical Discharge Machining): Ideal for intricate and delicate components.

- Diffusion Bonding: A cutting-edge technique that creates seamless, strong joins between molybdenum and other materials. This process is critical for applications requiring ultra-high vacuum or thermal conductivity.

Molybdenum Diffusion Bonding – Cooling Plate

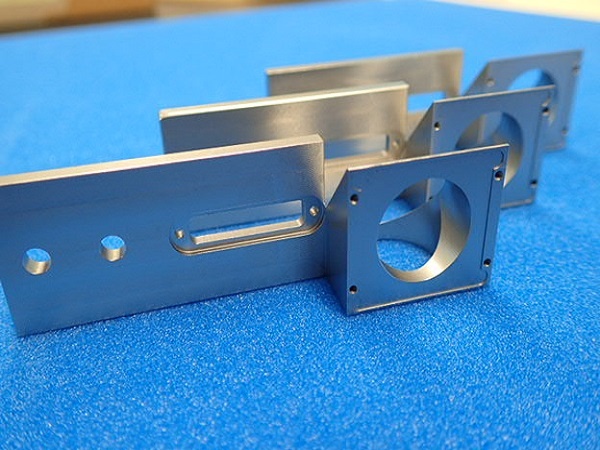

Applications of Custom Molybdenum Parts

Our molybdenum components are designed for critical roles in diverse industries:

- Aerospace: High-temperature parts like nozzles and heat shields.

- Semiconductors: Heat sinks, sputtering targets, and electrical contacts.

- Energy: Components for nuclear power systems, solar energy, and gas turbines.

- Medical Technology: High-performance imaging devices and surgical instruments.

Molybdenum Beam Monitor

Explore the Potential of Molybdenum with Top Seiko

From aerospace components to cutting-edge medical devices, molybdenum’s versatility and strength make it a cornerstone of modern engineering.

With advanced techniques like diffusion bonding, we’re able to push the boundaries of what’s possible, delivering innovative solutions for the most demanding applications.

Let Top Seiko help you unlock the full potential of molybdenum with precision machining tailored to your needs. Contact us today to discuss your next project.

Reach out to us today to discover how we can support your precision machining needs!

Further Reading and Resources

For more detailed information on other high-performance materials and their applications, visit the Top Seiko website : Top-Seiko.com