Precision in Titanium: A New Benchmark

2025.01.08Titanium crafted with absolute precision

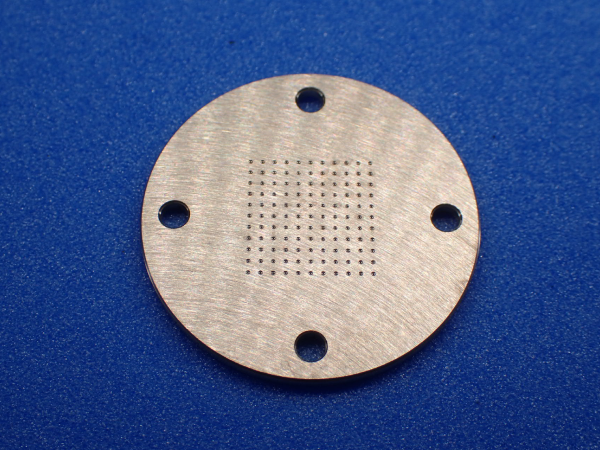

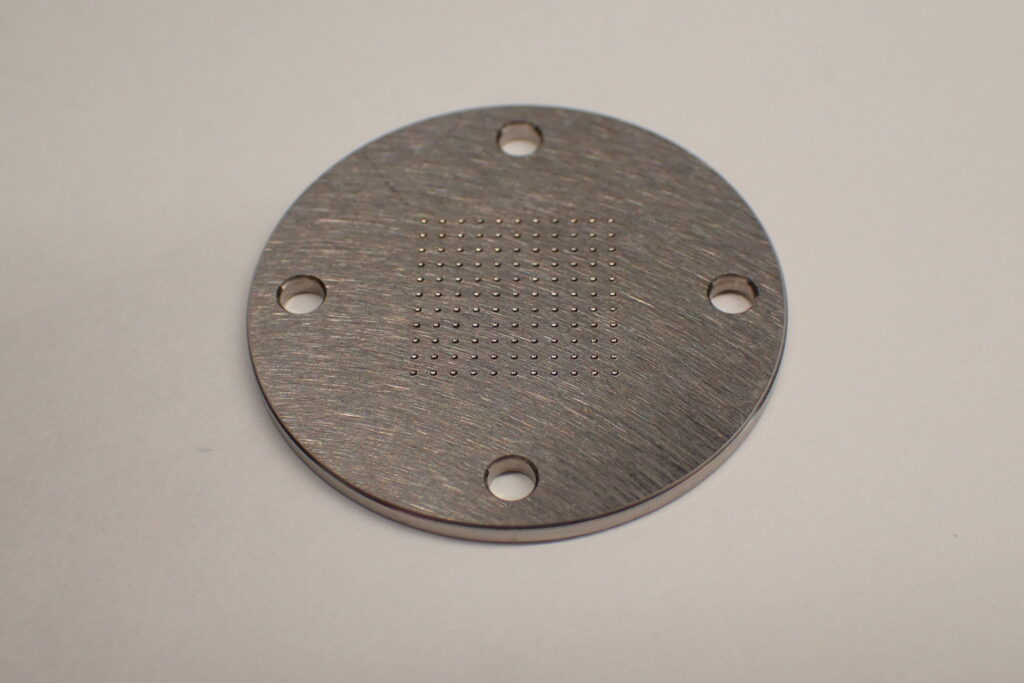

Titanium Grid

A titanium part with a diameter of 25 mm and a thickness of just 1 mm, featuring an intricate 11×11 grid of micro-holes with a diameter of only 0.1 mm each. This precision component represents the cutting edge of modern manufacturing and material engineering.

Using our state-of-the-art CNC machining center, we achieve levels of precision and consistency that push the boundaries of possibility.

Here’s what sets this part apart:

- Micromachining Excellence: Each micro-hole is drilled with sub-micron accuracy, ensuring flawless alignment and consistency across the entire grid.

- Surface Quality & Finish: Advanced machining techniques preserve the part’s structural integrity while delivering a smooth, defect-free surface.

- Material Optimization: Titanium’s exceptional properties—lightweight, corrosion-resistant, and incredibly strong—make this piece ideal for aerospace, medical, and precision engineering applications.

Why Precision Matters:

In components like these, every fraction of a millimeter counts. Whether it’s ensuring optimal airflow, facilitating advanced filtration, or supporting intricate medical devices, our expertise in micromachining delivers results that meet the strictest tolerances and performance standards.

At our core, we believe innovation and craftsmanship go hand in hand. By leveraging cutting-edge technology and years of expertise, we bring even the most ambitious designs to life.

Let’s work together to transform your vision into reality.

If you need precision machining for Titanium or other superhard materials, get in touch with us !

Discover how our specialized expertise can enhance your next project.

Further Reading and Resources

For more detailed information on other high-performance materials and their applications, visit the Top Seiko website : Top-Seiko.com