What is MMC Material? Properties and Applications

2025.03.20

Metal Matrix Composites (MMC) are advanced engineering materials in which a porous SiC structure is infiltrated with metallic silicon.

This combination enhances mechanical and physical properties, providing innovative solutions across various industries.

Key Properties of MMCs

- High Hardness and Wear Resistance: With ceramic reinforcements such as silicon carbide (SiC), MMCs exhibit exceptional hardness, making them highly resistant to wear and abrasion.

- Good Machinability: Despite their hardness, MMCs offer better machinability than pure ceramic materials like SiC. This enables the production of intricate and high-precision components while reducing manufacturing costs.

- Thermal Stability: MMCs maintain high performance at elevated temperatures, making them suitable for demanding thermal environments.

- Low Thermal Expansion: The combination of metal and ceramic reinforcement gives MMCs a low coefficient of thermal expansion, ensuring dimensional stability even under temperature variations.

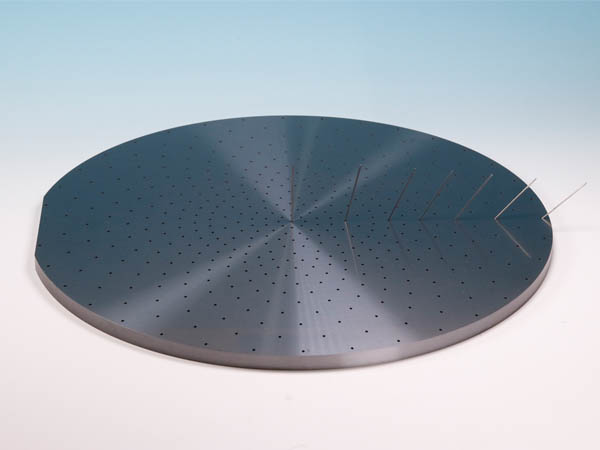

MMC shower plate

Common Applications of MMCs

Thanks to their unique properties, MMCs are widely used in various applications:

- Mechanical Components: Their strength and lightweight characteristics make them ideal for machine parts requiring high strength-to-weight ratios.

- Tools and Fixtures: MMCs are used in the manufacturing of jigs and fixtures that demand durability and precision.

- Aerospace and Automotive Industry: The combination of lightweight and strength makes MMCs suitable for structural components in aerospace and automotive applications.

- Heat Sinks and Thermal Management: Due to their high thermal conductivity, MMCs are used in electronic devices for heat dissipation and thermal management.

Examples of MMCs and Their Properties

| Material | Composition | Vickers Hardness (GPa) | Flexural Strength (GPa) | Max Operating Temperature (°C) | Thermal Expansion Coefficient (×10⁻⁶/°C) | Thermal Conductivity (W/(m·K)) |

|---|---|---|---|---|---|---|

| SS501 | SiC 50% / Si 50% | 50 | – | 1,200 | 2.8 (RT–200°C) | 175 |

| SS701 | SiC 70% / Si 30% | 50 | – | 1,200 | 3.0 (RT–200°C) | 190 |

| PARUCOCERAM SI | SiC 82% / Si 18% | 250 | 3 | 1,350 | 3.4 (RT–700°C) | 220 |

| SA701 | SiC 70% / Al 30% | 340 | 8 | – | 7.0 (RT–200°C) | 160 |

Conclusion

Metal Matrix Composites offer a versatile and advanced solution for various industrial applications.

Their combination of superior mechanical properties, machinability, and thermal stability makes them a preferred choice in industries requiring high-performance and reliability. Ongoing research and development in this field promise even more innovations and future applications.

Would you like to discuss a project with us? Reach out today!