Machinable Ceramics: Properties and Applications

2025.03.31

When it comes to precision machining, machinable ceramics offer unique advantages over traditional engineering ceramics.

Unlike their rigid counterparts, machinable ceramics can be easily processed using standard metalworking tools. This makes them perfect for creating intricate and highly detailed parts.

At Top Seiko, we specialize in machining high-performance materials like Photoveel, Macor, and Shapal Hi-M Soft, ensuring precision and quality in every component.

Why Choose Machinable Ceramics?

Machinable ceramics are the best choice for applications that demand high precision and rapid prototyping. They can be machined quickly and cost-effectively, without the need for expensive grinding or specialized tools. Top Seiko helps industries select the right machinable ceramic, providing expert guidance and precision machining services to meet specific needs.

Key Properties of Machinable Ceramics

-

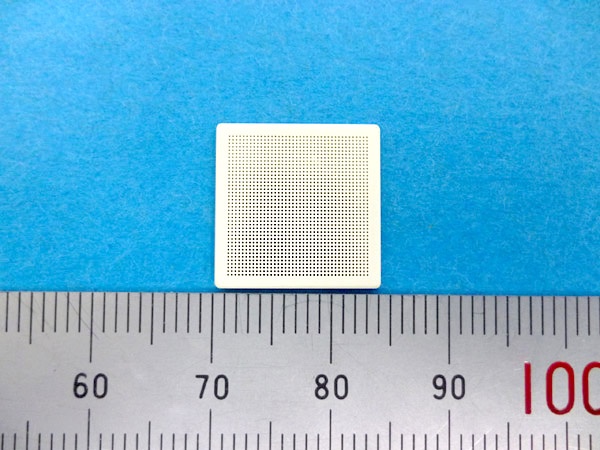

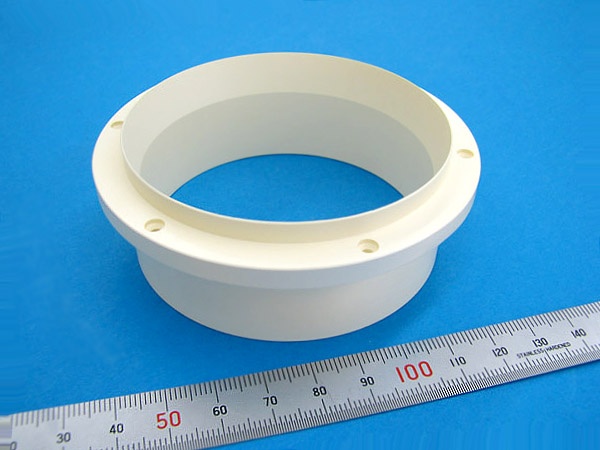

Easy to Machine: Machinable ceramics allow the creation of complex geometries, small features, and precise holes using standard machining techniques.

-

High Hardness and Strength: Fine-grained machinable ceramics can be nearly as strong as alumina.

-

Superior Heat Resistance: Materials with high Boron Nitride (BN), Silicon Nitride (Si3N4), or Aluminum Nitride (AlN) content can withstand extreme temperatures.

-

Wide Range of Thermal Expansion (CTE): Some machinable ceramics, like Shapal Hi-M Soft and BA-2000, have CTE values similar to silicon, making them ideal for semiconductor applications.

-

High Thermal Shock Resistance: Machinable ceramics with BN, Si3N4, and AlN provide excellent resistance to rapid temperature changes.

-

Excellent Dielectric Strength: Macor and Boron Nitride are top choices for high-performance electrical insulation.

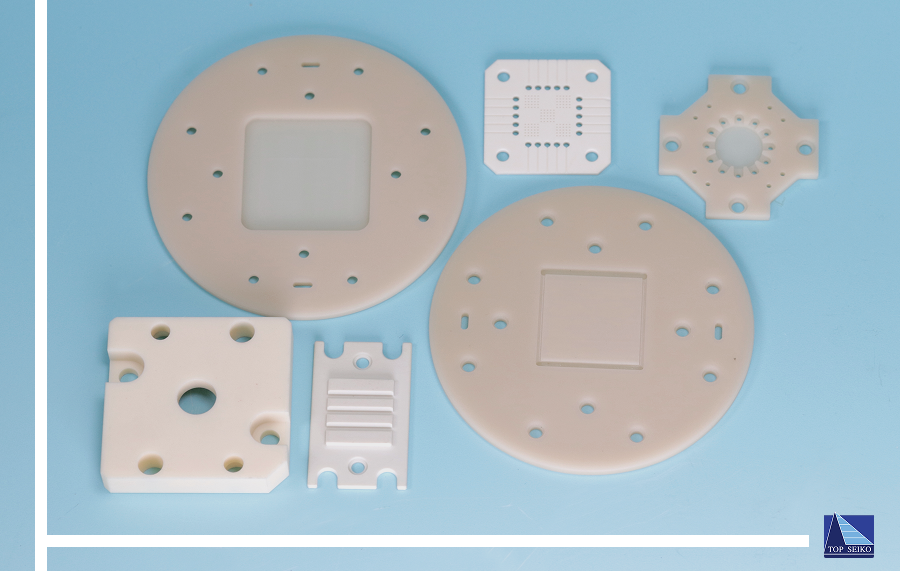

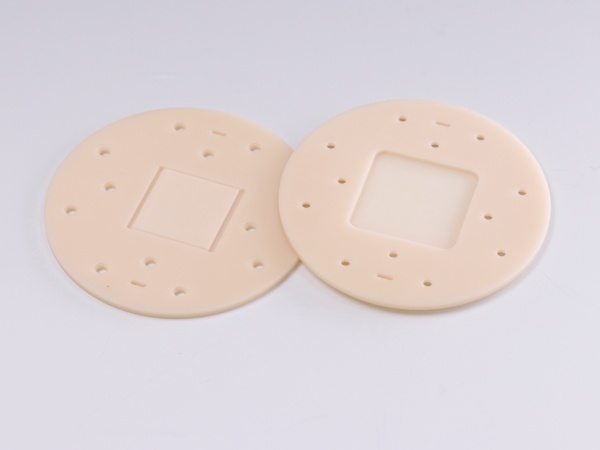

Machinable Ceramics machined parts

Common Applications of Machinable Ceramics

Due to their outstanding properties, machinable ceramics are widely used in various industries. Some key applications include:

-

High-Temperature Fixtures and Components – Essential for aerospace and industrial applications.

-

Precision Parts for Semiconductor Manufacturing – Ideal for components that must match silicon’s CTE.

-

Components for Rapid Heating and Cooling Environments – Used in glass manufacturing and lab equipment.

-

High-Temperature Electrical Insulators – Critical for electronic and power applications.

Why Choose Top Seiko for Machinable Ceramics?

At Top Seiko, we provide comprehensive precision machining services, including material selection assistance and sourcing.

We help clients choose the right machinable ceramic based on their specific requirements.

Our expertise ensures that every part is manufactured to the highest standards, meeting even the most demanding applications.

Macerite Product

Final Thoughts

Machinable ceramics like Photoveel, Macor, and Shapal Hi-M Soft offer the perfect balance of machinability and high-performance properties.

Their ability to be easily machined, withstand high temperatures, and provide excellent dielectric strength makes them indispensable in advanced manufacturing. Trust Top Seiko for expert guidance and high-precision machining solutions. Contact us today to discuss your project!