Silicon Carbide – Key Properties and Industrial Applications

2025.04.15

At Top Seiko, we specialize in the precision machining of advanced ceramics and composite materials, including one of the most robust and versatile materials available today—Silicon Carbide (SiC).

Renowned for its exceptional mechanical, thermal, and chemical properties, Silicon Carbide has become a go-to material across a wide range of demanding industrial applications.

What is silicon carbide ?

Silicon Carbide is a compound of silicon and carbon, known for its high hardness, excellent thermal stability, and outstanding chemical resistance. Unlike many materials that degrade at elevated temperatures, SiC retains its strength even in extreme heat and chemically aggressive environments.

These properties make it an ideal choice for industries such as semiconductor manufacturing, aerospace, energy, and chemical processing.

Let’s take a closer look at what makes SiC stand out:

Key Properties of Silicon Carbide

-

High Hardness & Wear Resistance: SiC ranks just below diamond on the Mohs hardness scale, making it extremely resistant to abrasion and scratching.

-

Thermal Stability: It offers high thermal conductivity, low thermal expansion, and can withstand rapid temperature changes—ideal for environments involving thermal shock.

-

Chemical Resistance: SiC maintains excellent resistance to acids, alkalis, and molten salts up to 800°C, ensuring long service life in corrosive conditions.

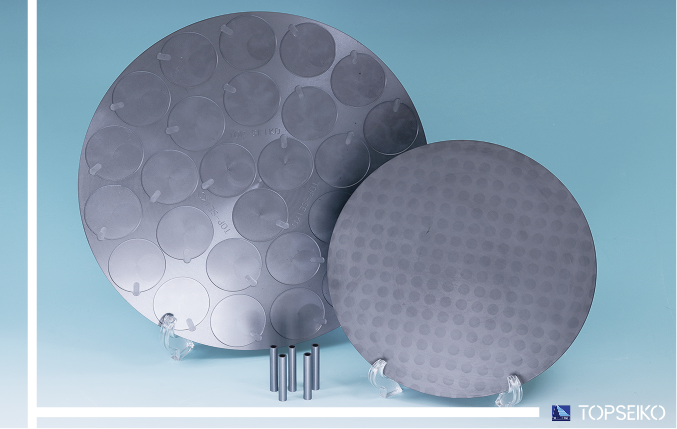

High Purity 99.9% SiC Tray

Popular Applications of SiC Components

Thanks to its unique combination of properties, Silicon Carbide is widely used in components that must endure high temperatures, abrasive wear, and corrosive chemicals.

| Application Area | Examples of SiC Use |

|---|---|

| Semiconductor & Electronics | Wafer carriers, wafer tray supports |

| Aerospace & Energy | Turbine components, heat exchangers, thermal shields |

| Industrial Equipment | Blast nozzles, mechanical seals, bearings |

| Chemical Processing | Components exposed to acids, alkali, or reactive gases |

Top Seiko’s Expertise in Machining Silicon Carbide and Si-SiC MMCs

Machining Silicon Carbide requires specialized knowledge and ultra-precise tools due to its hardness and brittleness. At Top Seiko, we’ve built a strong reputation for delivering high-precision SiC components with tight tolerances and complex geometries.

In addition to pure SiC, we also have extensive experience working with Silicon – Silicon Carbide Metal Matrix Composites (Si-SiC MMCs). These composites combine the strength and wear resistance of SiC with the machinability and thermal conductivity of Silicon, making them ideal for applications where thermal management and structural integrity are critical.

SiC Sealing Cap for Process Chamber

Looking for High-Performance SiC Components?

Whether you need custom-made SiC parts for semiconductor manufacturing, or high-strength components for high-temperature chemical environments, Top Seiko is here to help. Our team of experts can assist you in material selection, design optimization, and ultra-precision machining.

Contact us today to learn more about our Silicon Carbide machining capabilities or request a quote for your next high-performance component !