What Can Diffusion-Bonded Components Really Do?

2025.08.06

During a recent trade show, someone asked a thoughtful and surprisingly common question:

“What are diffusion-bonded parts with internal structures actually used for?”

This technology plays a key role in high-tech manufacturing, yet many people overlook its potential. Let’s explore it in more detail.

What Is Diffusion Bonding?

Diffusion bonding joins solid materials using heat and pressure over time. The process doesn’t melt the parts. Instead, atoms migrate across the surfaces until the two components fuse into one.

This method becomes especially valuable when engineers design internal features—such as micro-channels, holes, or cavities—before bonding. After bonding, the structure becomes one sealed, solid component. The result is a compact, leak-tight part with clean internal geometry.

Why Use It for Complex Geometries?

Conventional welding or brazing often fails when precision and internal complexity are critical. Trying to close off tiny channels or seal fragile cavities risks deformation or contamination.

Diffusion bonding solves this. Engineers can machine fine details first, then bond the structure to create an internal system with no joints or welds. This approach protects the geometry and ensures high structural integrity.

Where It Delivers Real Value

You’ll find this technology especially useful in industries like aerospace, semiconductors, and energy.

In aerospace, bonded parts with microchannels support high-performance thermal management in compact, lightweight forms.

Semiconductor tools require ultra-clean, sealed systems. Diffusion-bonded ceramics or metals ensure purity, vacuum integrity, and chemical resistance.

Power systems and electronics also benefit: embedded cooling channels reduce heat buildup without increasing part size or complexity.

What Materials and Performance Can You Expect?

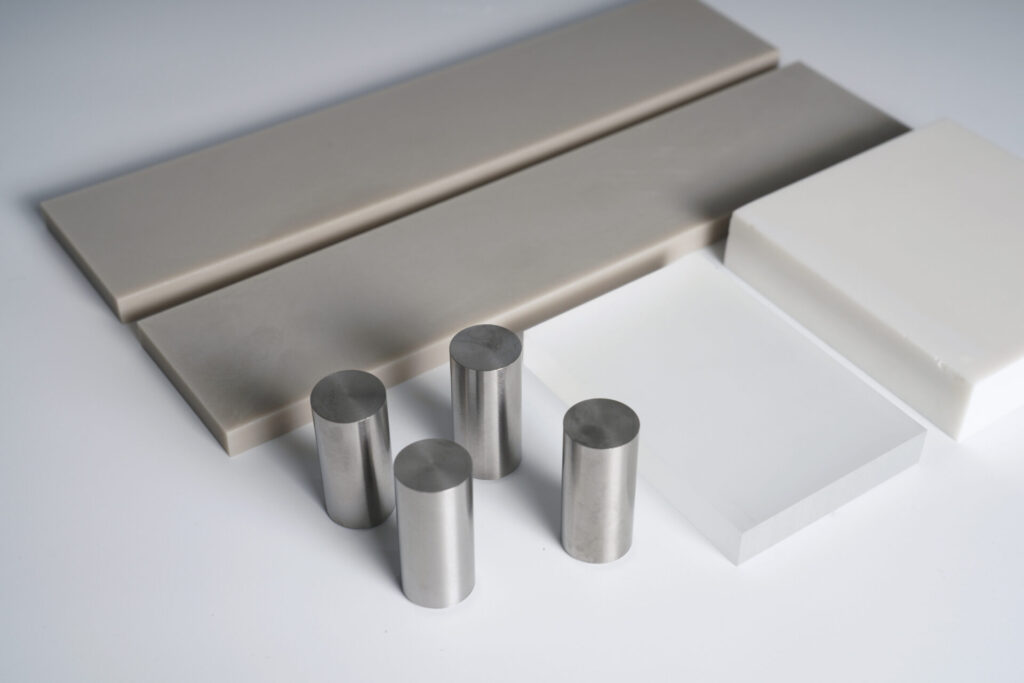

At Top Seiko, we bond materials that are difficult to join using traditional methods. These include molybdenum, nickel, quartz glass, alumina, and SiSiC—each bonded to itself.

Our test pieces show extremely low helium leak rates—well suited for vacuum systems, high-purity setups, and corrosive environments. We also continue to refine our process as new applications emerge.

What Are the Limits and the Opportunities?

Currently, we focus on bonding two or three layers of the same material. While the process doesn’t yet scale easily to large volumes or mixed-material stacks, it delivers exceptional results when precision and reliability matter most.

Why This Technology Matters

So, what can these parts actually do?

They allow you to integrate functionality directly into the structure—cooling paths, flow channels, sealed cavities—without glues, welds, or mechanical joins. That means fewer risks, cleaner performance, and better long-term durability.

Let’s Build the Future Together

At Top Seiko, we specialize in ceramic and refractory metal components with internal complexity. Our team partners with industries that need clean, compact, high-performance solutions.

If your project demands precision, cleanliness, and internal complexity — let’s talk.

We’re ready to help you explore what’s possible.