“TOP Machining Technology” – Chapter 1 (Cont.13)

2023.01.30

Processing of “hard and brittle” materials has become a national challenge.

Among these, “hard and brittle” materials require special processing techniques.

For example, a national budget for the development of new materials (Development of Innovative New Structural Materials and Other Technologies) has been established for a nine-year period from 2014 to 2022.

The purpose of the project is to develop technologies that will lead to a drastic weight reduction of transportation equipment (automobiles, vehicles, etc.), which will have a significant impact on reducing energy consumption and CO2 (carbon dioxide) emissions. What is interesting is the direction of materials development indicated in this project. The theme of the project is “The development of materials that combine strength and workability”.

As the strength of a material increases, its ductility decreases (i.e., it becomes more brittle), making it more difficult to process. Since material strength and ductility are generally incompatible, the processing of “hard and brittle” materials has become a national challenge. Of course, each material has its own suitable machining direction, so it is not possible to assign a superior or inferior technical difficulty level, i.e., what characteristics of a material make it most difficult to cut. Processing soft and sticky materials such as aluminum requires special surface treatment and chipping treatment, and in the case of titanium alloys, chip removal technology is indispensable to protect the blade. While the point of technological pursuit differs depending on the characteristics of the material, “hard and brittle” in the sense that it is necessary to invest national budgets to develop materials with both strength and workability. It is safe to assume that processing the material is challenging. And the processing of this “hard and brittle” material is, as we have already mentioned, the field in which we at TOP SEIKO are specialized.

Processing of “hard and brittle” materials supports cutting-edge research and development.

Basic materials, mainly steel, are used in all market sectors, but materials are becoming increasingly diversified, including silicon, a semiconductor material, rare elements, fine ceramics, FRP, and resins.

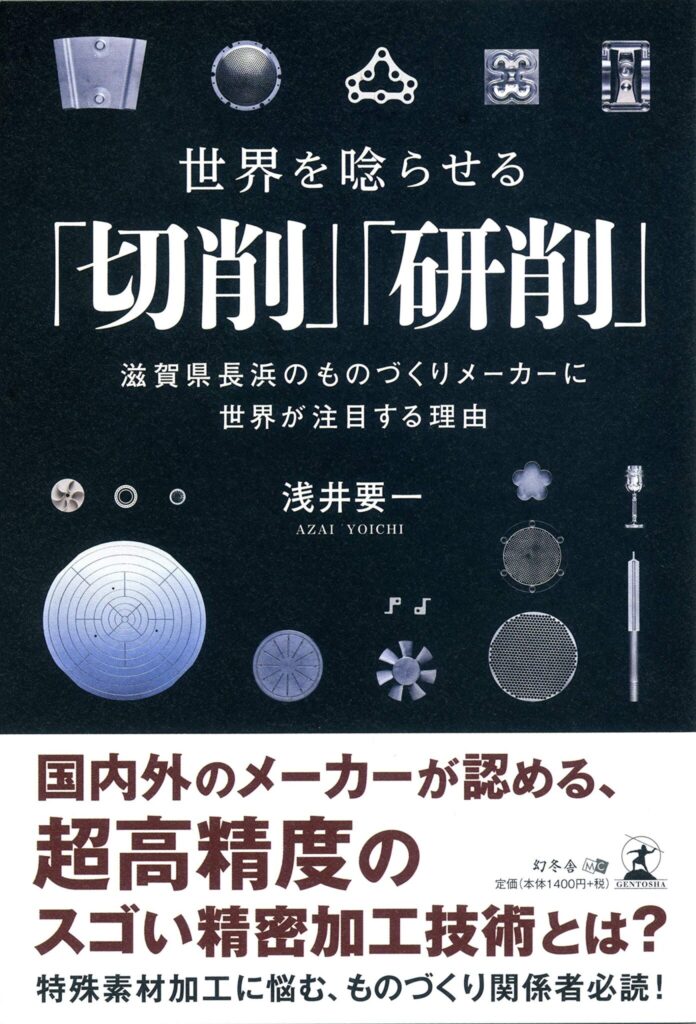

Of these materials, Top Seiko mainly processes rare elements (tungsten, molybdenum, tantalum, etc.), fine ceramics, and glass.

Rare elements and fine ceramics are found mainly in new areas of the market, as in automotive parts, motors, fuel cells, catalysts, information and communication equipment, and the medical field. Furthermore, there is a growing need for rare elements, fine ceramics, and glass in space development and industrial machinery, which are not on the list. These “hard yet brittle” new materials are not limited to automobiles and other transportation equipment, but tend to be sought after in cutting-edge research and development. In other words, specializing in the processing of hard and brittle materials is nothing less than supporting the field of research and development.