High Precision / Micro Machining Services

Top Seiko provides high precision and micro machining services for a wide variety of exotic hard materials. Our well-equipped & maintained facilities combined with our in-depth knowledge and extensive machining experience of hard materials, we manufacture highest quality custom machined parts.

| Manufacturing environment |

|

|---|---|

| Equipment |

|

| Tools |

|

| Fixtures / Jigs |

|

| Staff |

|

| Machining conditions |

|

| Knowledge of materials |

|

| Materials we machine include |

|

| Quality Assurance |

|

Machining Tolerances for High Precision / Micro Machining Parts

| Features | Tolerances (unit: mm) | |

|---|---|---|

| Normal | Tight | |

| Pitch | ±0.05 | ±0.003 |

| Inner/Outer Diameter | ±0.05 | ±0.003 |

| Thickness | ±0.05 | ±0.002 |

| Height of Step / Column | ±0.05 | ±0.003 |

| Depth of Counterbore | ±0.05 | ±0.003 |

| Hole Diameter | ±0.1 | ±0.005 |

| Thread | Go: inspected with a thread gauge | No go: inspected with a pin gauge of the pilot hole size |

| Flatness | 0.05 | 0.003 |

| Parallelism | 0.05 | 0.005 |

| Roundness | 0.05 | 0.005 |

| Cylindricity | 0.05~0.1 | 0.005 |

| Surface Roughness | Ra0.8 | Ra0.05 |

Machining samples

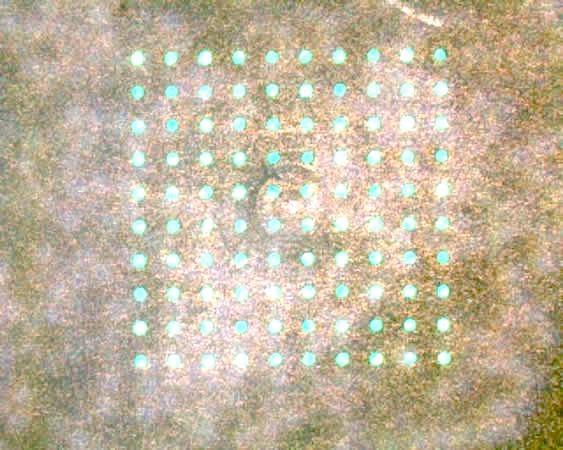

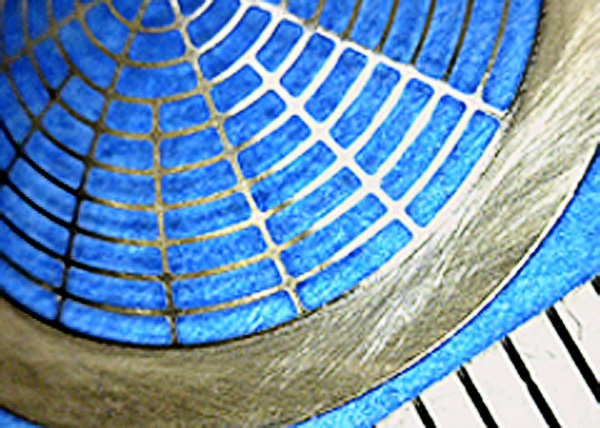

Molybdenum Custom Machined Sample

Molybdenum Custom Machined Sample: Thickness 0.05, Frame width: 0.05

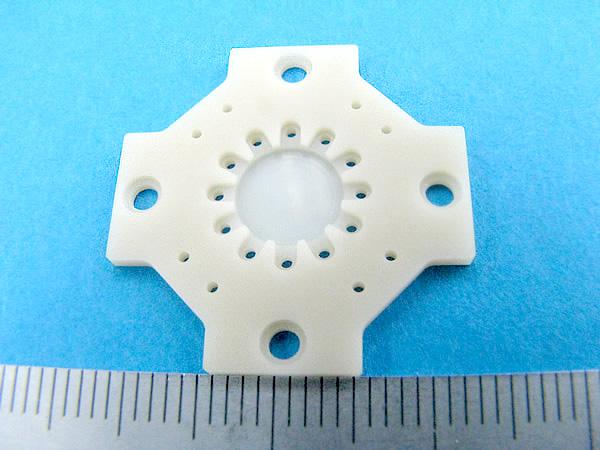

Probe Guard Jig

Probe Guard Jig: φ0.07 x 100 PL for Machinable Ceramics

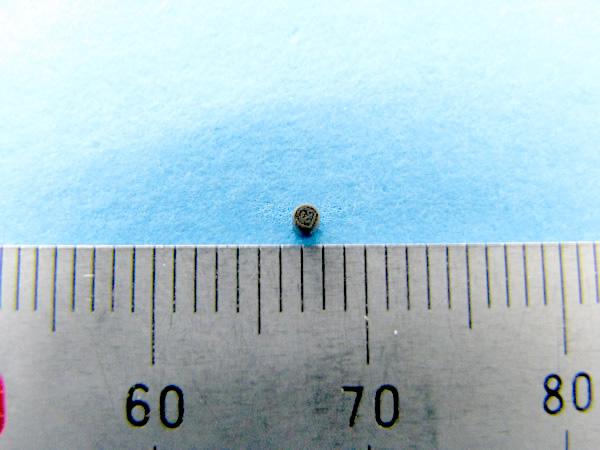

Micro Machined Product

φ

Size: φ1 x thickness 1mm

Material: Black Alumina

The groove width and depth are 0.07 mm.