Hole Drilling – Precision & Multiple Hole Drilling

Many parts require hole drilling process. It is one of the most common and basic machining processes. Each drilled hole usually plays an important role for the part to function and has to be produced exactly according to the specification. When drilling multiple holes in a part, it is important to set proper drilling conditions to maintain stable processing because a single failure in a hole can ruin the entire part.

We, at Top Seiko, quantify drilling load by measuring tool load to develop the most suitable drilling tool and establish the optimal processing conditions.

| Materials compatible with our hole drilling services | Advanced Ceramics, Fused Silica Glass (Fused Quartz), Glass Ceramics, Borosilicate Glass (Tempax), Silicon, Machinable Ceramics, Metal Ceramic Composite Materials, Molybdenum, Tungsten, and Tantalum. |

|---|---|

| Hole Drilling Capabilities |

Hole Diameter: micro holes, small-diameter holes, medium and large sized holes Hole Depth: 0.05~400mm Hole Shapes: straight, tapered, squared, and tapped holes Hole Diameter Accuracy:±0.005~0.1mm Number of holes per part: 1~5,000 |

| Machines We Use |

Machining Centers: 3-Axis / 5 Axis machining centers with center-through type coolant systems*, and high speed linear-motor machining centers Combined Lathes Hole Drilling EDM Machine Wire EDM Machine *Center-through type coolant system supplies high-pressure coolant to the tool tip through the hole in the spindle and tool for effective chip-flashing, cooling and prolonging tool life. |

| Drilling tool materials | tungsten carbide, diamond grains, single-crystal diamond, diamond coating, and compax. |

Top Seiko’s Machining Capabilities for Each Material

Machinable Ceramics

| Hole Diameter(㎜) | Maximum Depth-to-Diameter Ratio(㎜) | Hole Diameter Accuracy(㎜) | Maximum Number of Holes |

|---|---|---|---|

| 0.05~0.1 | 10:1 | ±0.005~±0.01 | 100~5,000 |

| 0.1~0.2 | 10:1 | ±0.005~±0.02 | 5,000 |

| 0.2~1.0 | 20:1 | ±0.005~±0.02 | 5,000 |

| 1.0~ | 30:1 | ±0.005~±0.05 | 5,000 |

Alumina, like other advanced ceramics, is very hard and brittle, making some parts impossible or too expensive to produce. Having superior machinability, machinable ceramics can usually be an excellent replacement for Alumina or even other hard materials. Although each machinable ceramic has unique properties, you may find the one that meets your property and cost requirements. There are many successful cases of such material replacements.

Fused Silica Glass (Fused Quartz), Borosilicate Glass, Silicon

| Hole Diameter(㎜) | Maximum Depth-to-Diameter Ratio(㎜) | Hole Diameter Accuracy(㎜) | Maximum Number of Holes |

|---|---|---|---|

| 0.05~0.1 | 10:1 | ±0.005~±0.01 | 10~200 |

| 0.1~0.2 | 10:1 | ±0.005~±0.01 | 200~500 |

| 0.2~0.4 | 20:1 | ±0.005~±0.05 | 500~2,000 |

| 0.4~1.5 | 30:1 | ±0.01~±0.05 | 2000~5,000 |

| 1.5~ | 30:1 | ±0.01~±0.05 | 5,000 |

Alumina, Aluminum Nitride

| Hole Diameter(㎜) | Maximum Depth-to-Diameter Ratio(㎜) | Hole Diameter Accuracy(㎜) | Maximum Number of Holes |

|---|---|---|---|

| 0.05~0.1 | 10:1 | ±0.005~±0.01 | 50 |

| 0.1~0.2 | 10:1 | ±0.005~±0.02 | 50~100 |

| 0.2~0.4 | 20:1 | ±0.005~±0.05 | 100~500 |

| 0.4~1.5 | 30:1 | ±0.005~±0.05 | 500~3,000 |

| 1.5~ | 30:1 | ±0.005~±0.1 | 500~3,000 |

Silicon Carbide, Zirconia, Silicon Nitride

| Hole Diameter(㎜) | Maximum Depth-to-Diameter Ratio(㎜) | Hole Diameter Accuracy(㎜) | Maximum Number of Holes |

|---|---|---|---|

| 0.1~0.3 | 10:1 | ±0.01~±0.05 | 20 |

| 0.3~0.5 | 10:1 | ±0.01~±0.05 | 50 |

| 0.5~1.5 | 20:1 | ±0.01~±0.05 | 50~100 |

| 1.5~ | 20:1 | ±0.01~±0.05 | 200 |

Molybdenum, Tantalum

| Hole Diameter(㎜) | Maximum Depth-to-Diameter Ratio(㎜) | Hole Diameter Accuracy(㎜) | Maximum Number of Holes |

|---|---|---|---|

| 0.05 | 10:1 | ±0.005~±0.01 | 100 |

| 0.05~0.2 | 10:1 | ±0.005~±0.01 | 100~500 |

| 0.2~2.0 | 20:1 | ±0.01~±0.05 | 500~3,000 |

| 2.0~ | 30:1 | ±0.01~±0.05 | 3,000 |

Machining Example

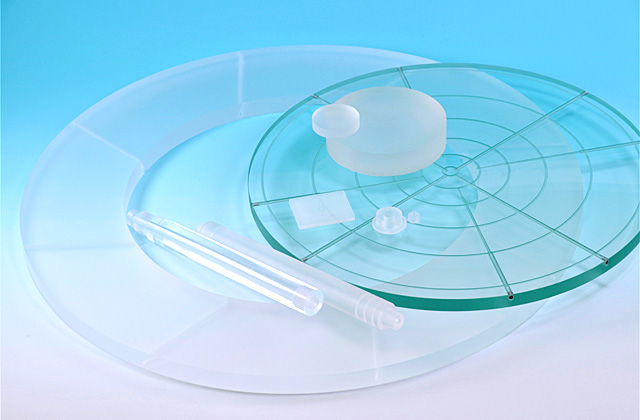

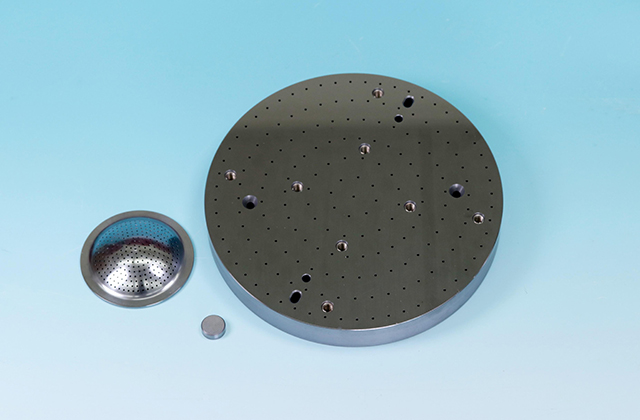

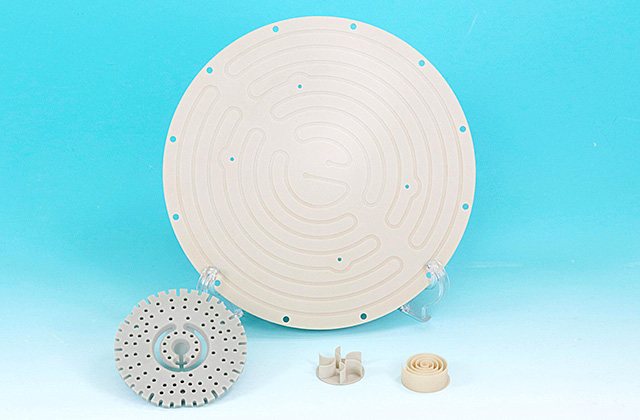

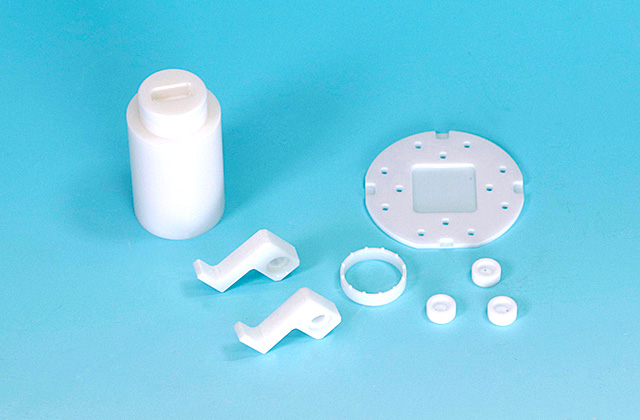

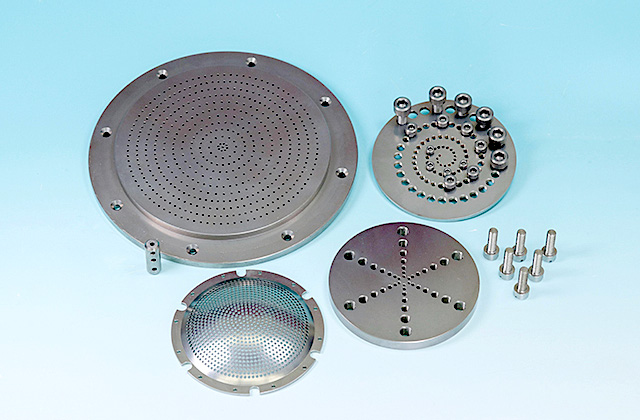

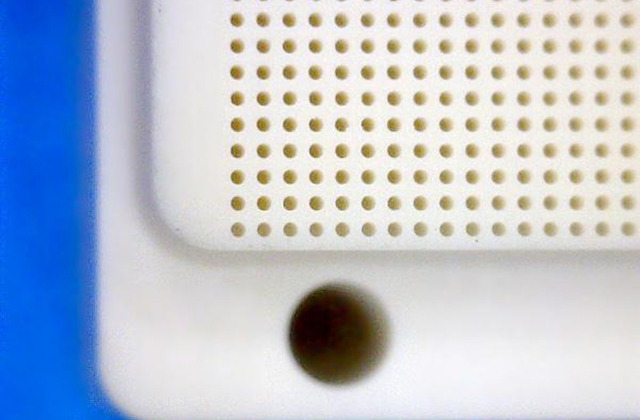

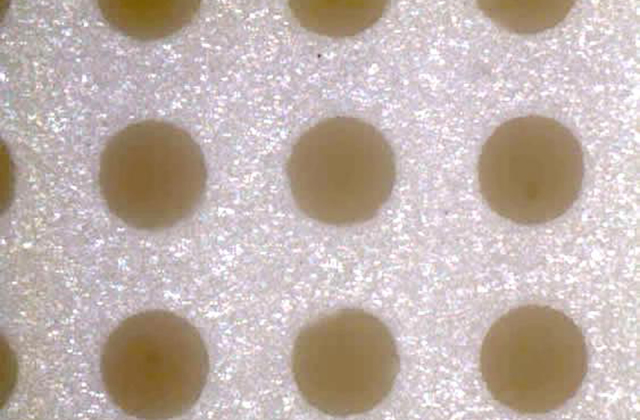

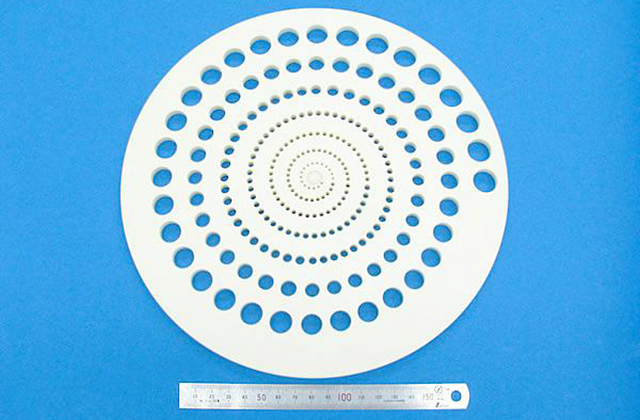

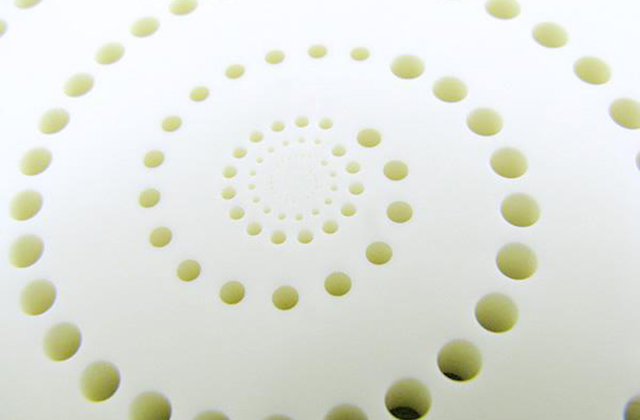

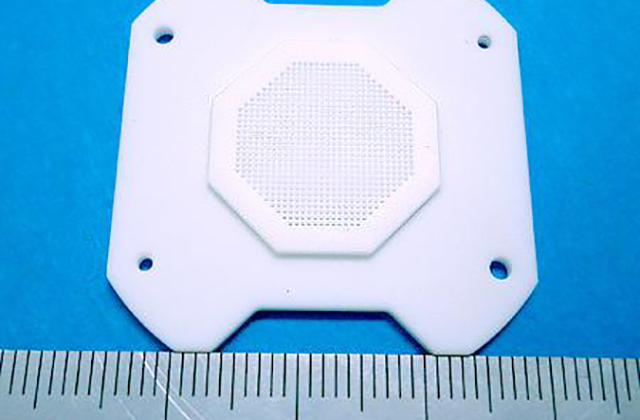

Shower Plate

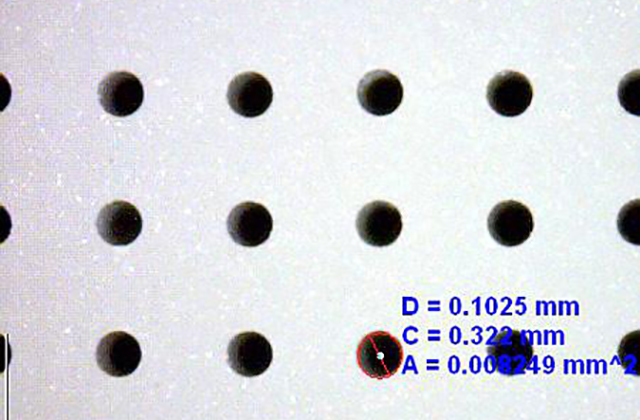

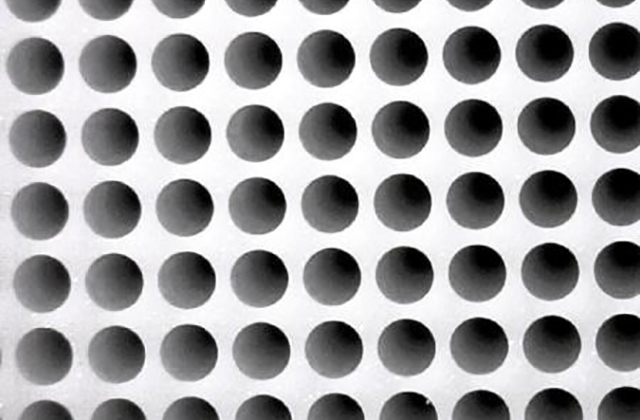

Machining Example: φ0.1 x 1,000 PL for Macerite SP

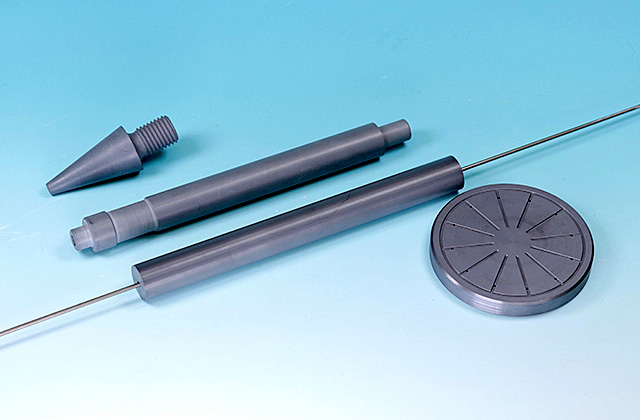

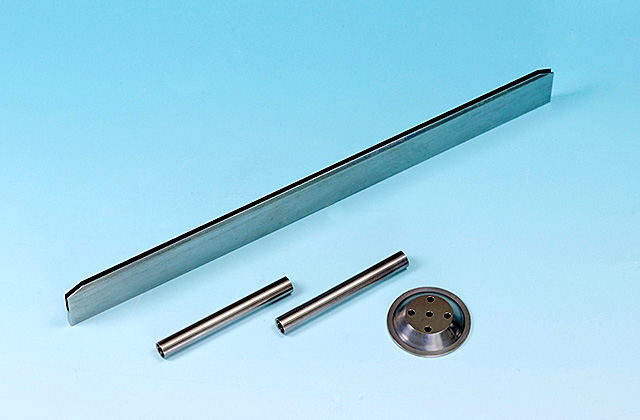

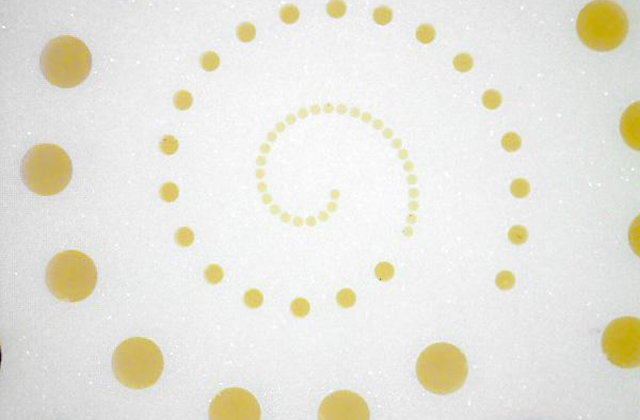

Gas Nozzle

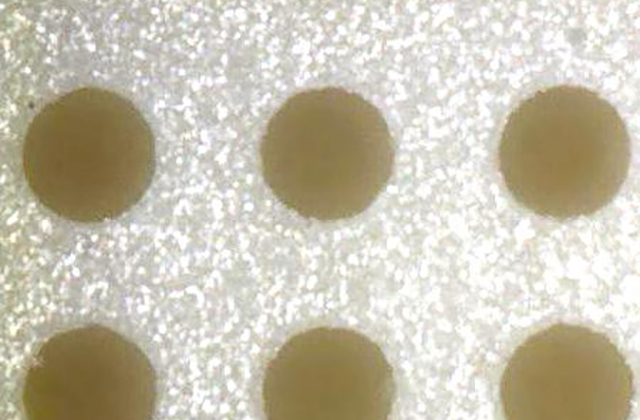

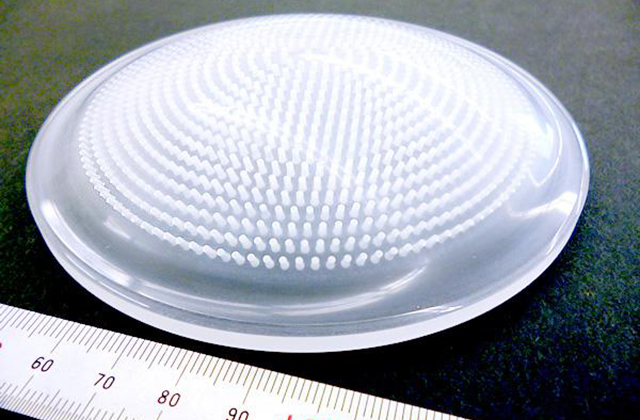

Machining Example: φ0.1 x 1,650 PL for Shapal Hi M-Soft

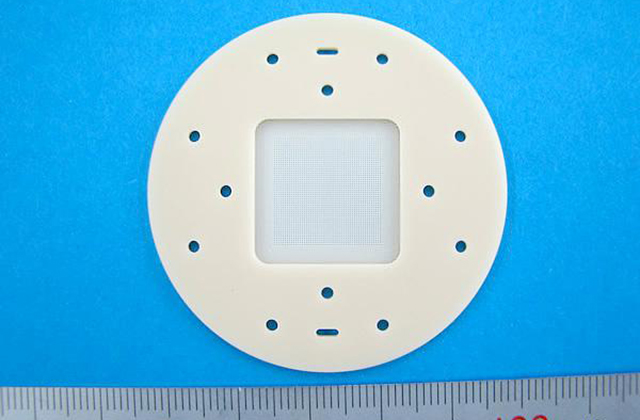

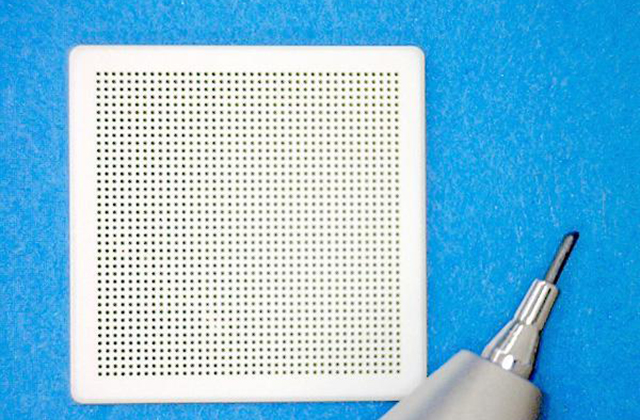

Filter

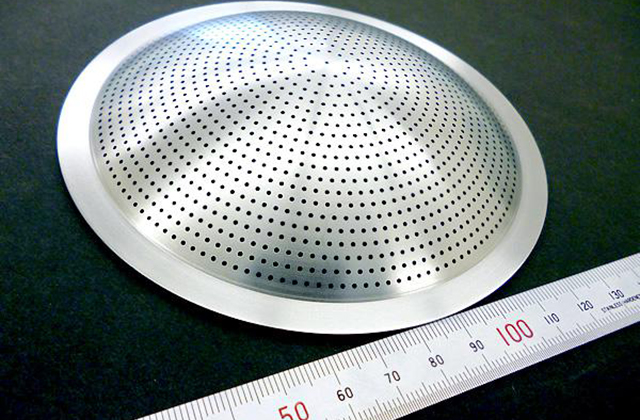

Machining Example: φ0.05 x 6,000 PL for Machinable Ceramics

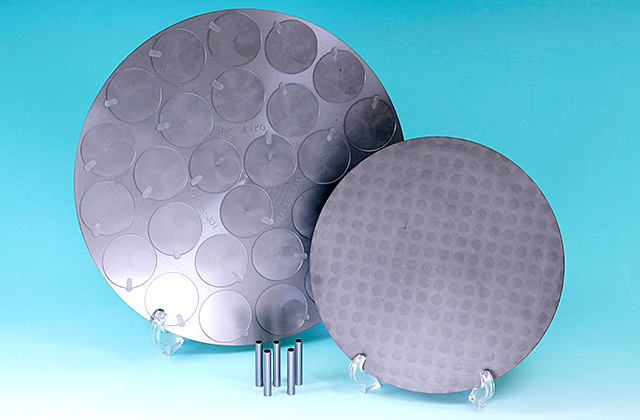

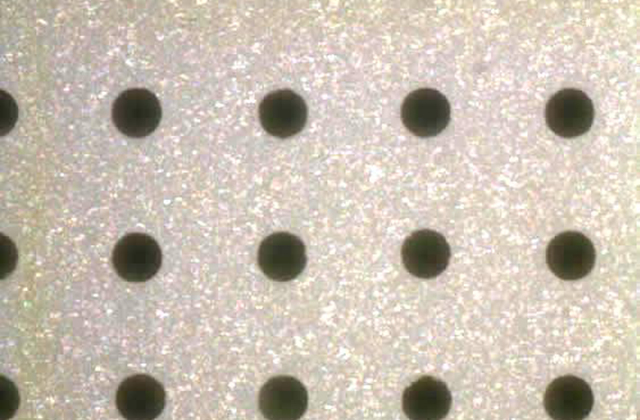

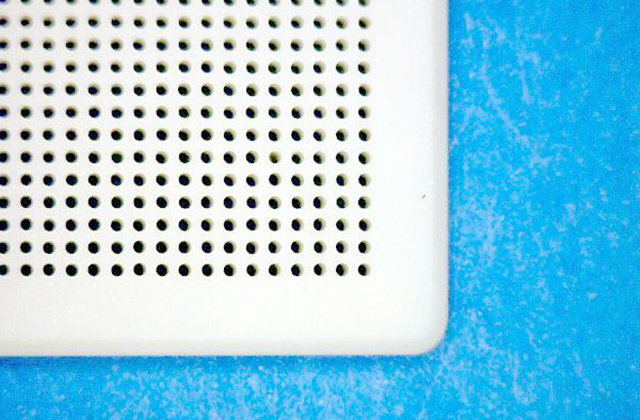

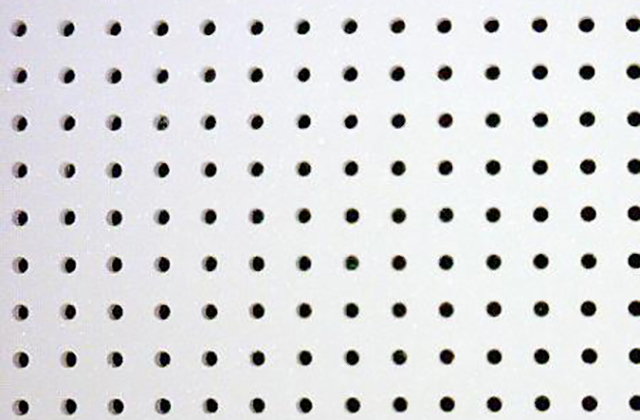

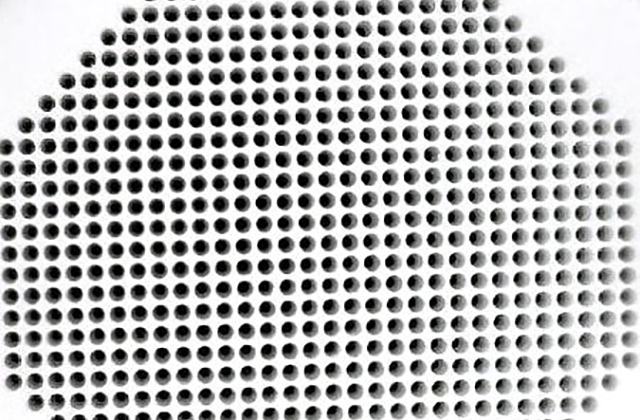

Hole Drilling Example

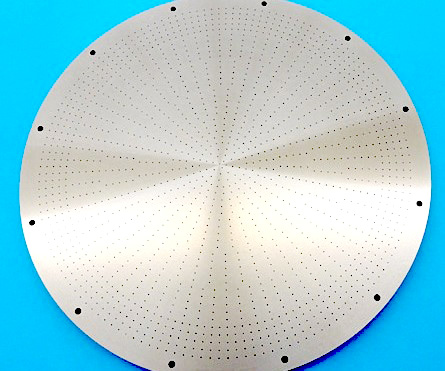

Drilling Example: φ0.1~φ16.0 for Alumina 99.5% plate

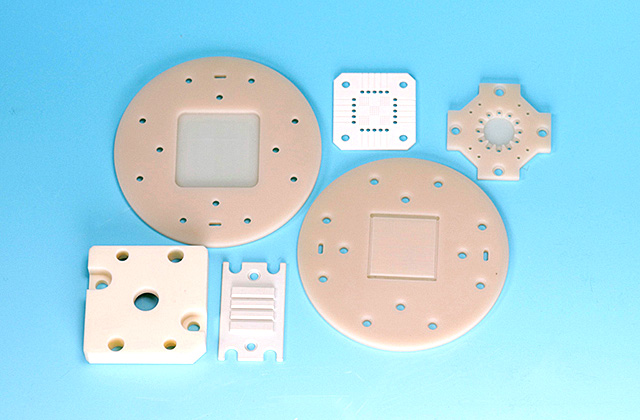

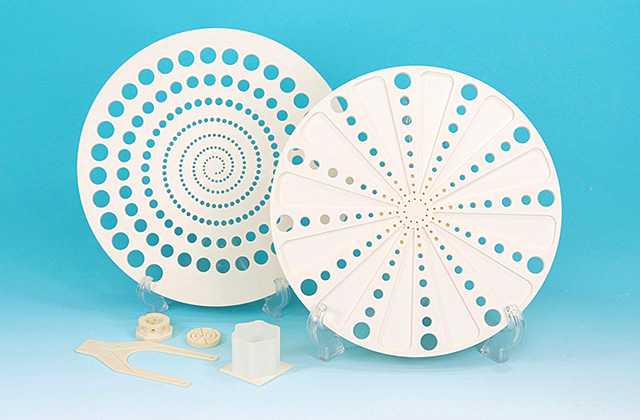

Custom Machined Product Examples

Micro Holes Drilling: φ0.1 x 6,000 PL

Micro Holes Drilling: φ0.1 x 3,000 PL