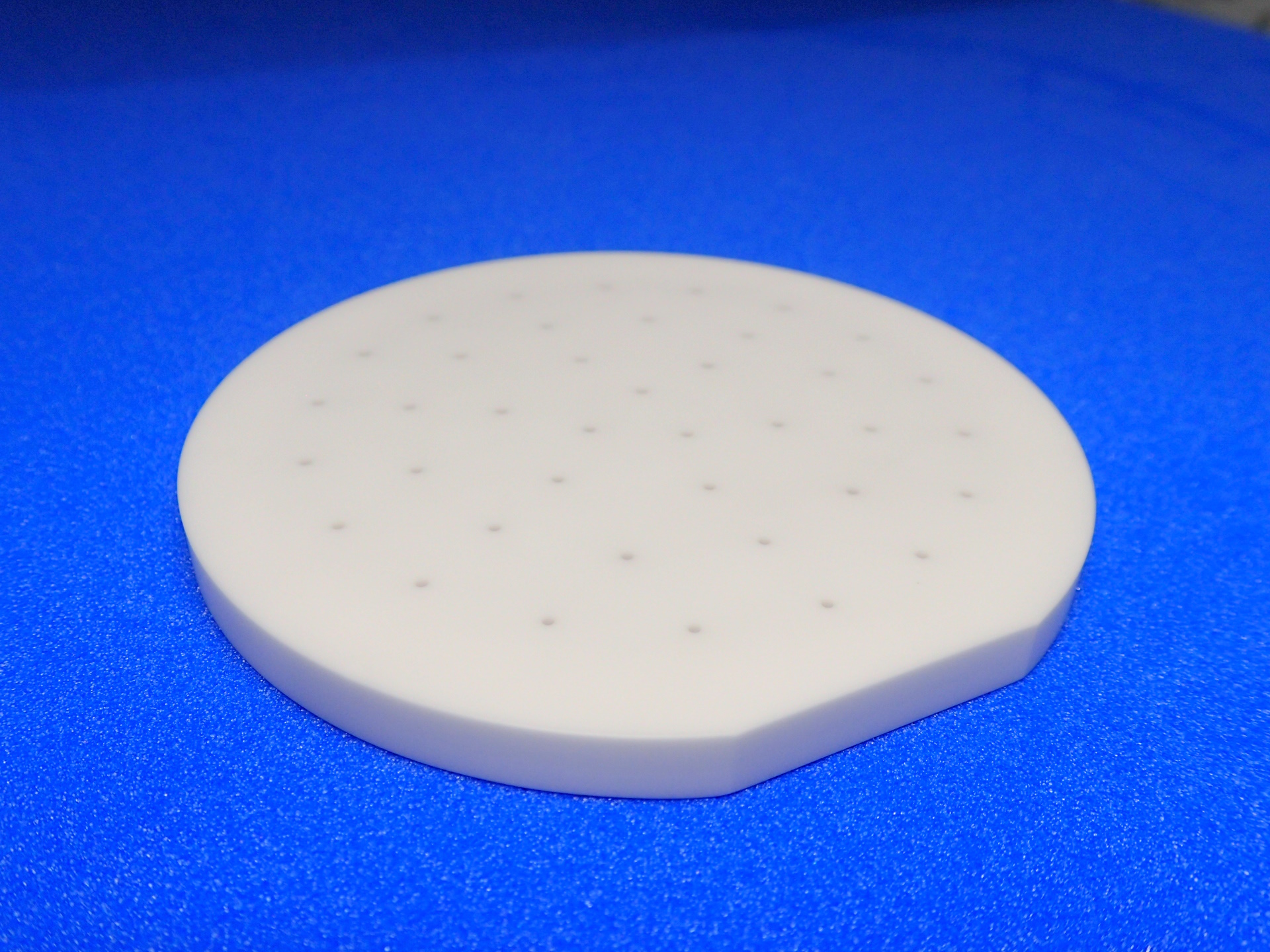

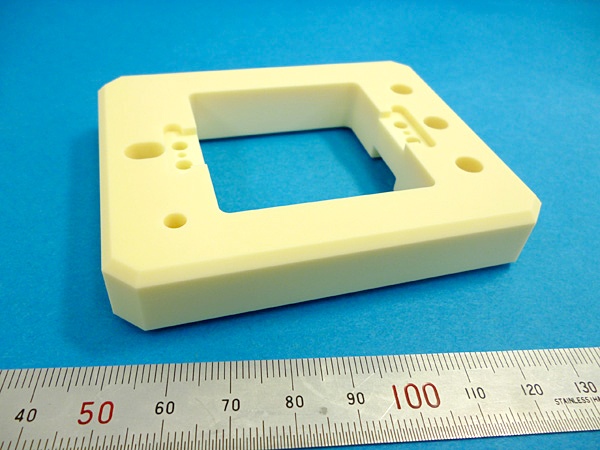

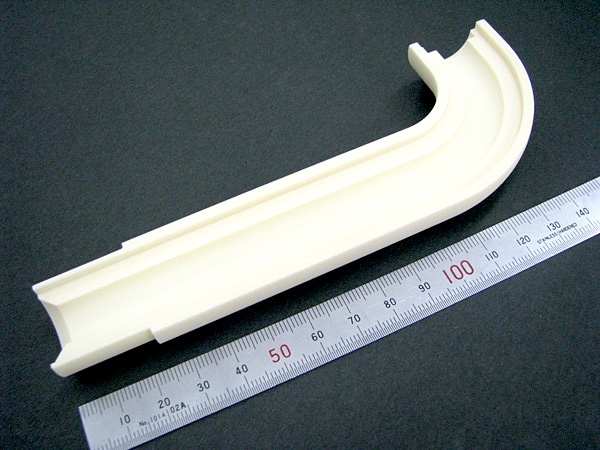

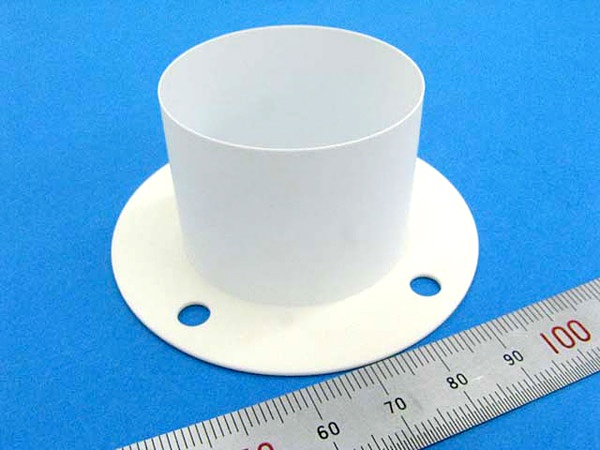

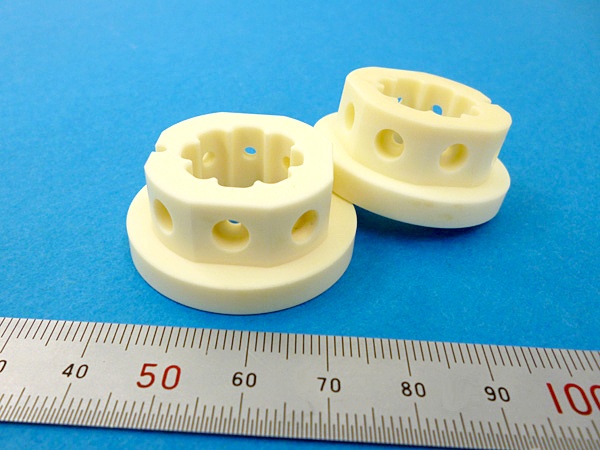

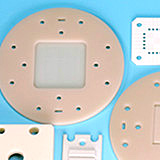

Alumina (Al2O3) – Custom Machined Parts

Alumina, also known as Aluminum Oxide, is the most popular ceramic material. It is a relatively low cost ceramic material with good machinability and has a very wide range of applications.

Alumina Properties

| Property | Vickers Hardness (GPa) | Fracture Toughness (MPa· m1/2) | Max Use Temperature(℃) | Coefficient of Thermal Expansion(×10-⁶/℃) | Thermal Conductivity (W/(m・K)) |

Thermal Shock Resistance(℃) | Dielectric Strength(kv/mm) | Chemical Resistance |

|---|---|---|---|---|---|---|---|---|

| Chemical Formula & Purity | ||||||||

| Al₂O₃ 99.5% |

18 | 4 | 1,300 (in air) |

8.5 (1000℃) |

30 | 200 | >10 | Good |

| Al₂O₃ 99.9% |

18 | 4 | 1,500 (in air) |

8.8 (1000℃) |

33 | 200 | >10 | Good |

Alumina – Key Properties & Popular Applications

| Key Properties | Applications | |

|---|---|---|

| High Hardness | Alumina has high wear resistance due to its high hardness. It also has good resistance to breaking and cracking due to its high fracture toughness and flexural strength. |

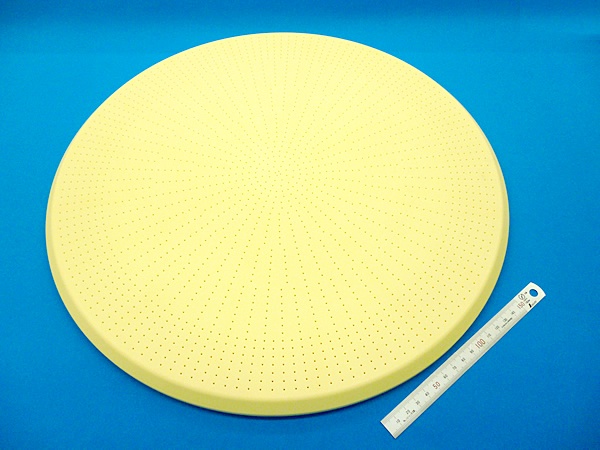

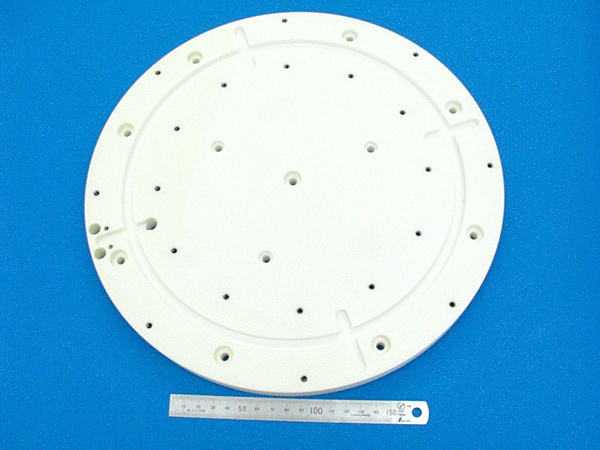

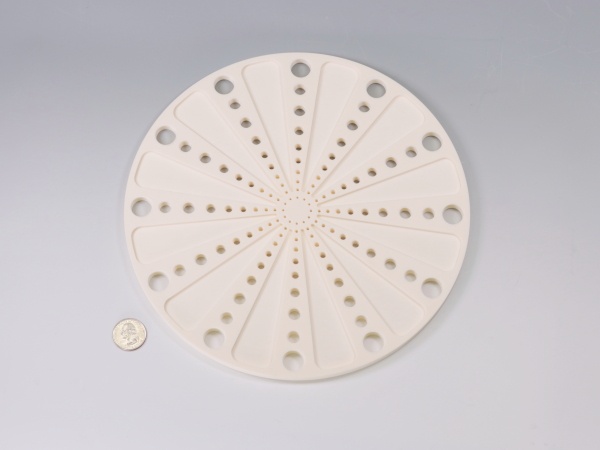

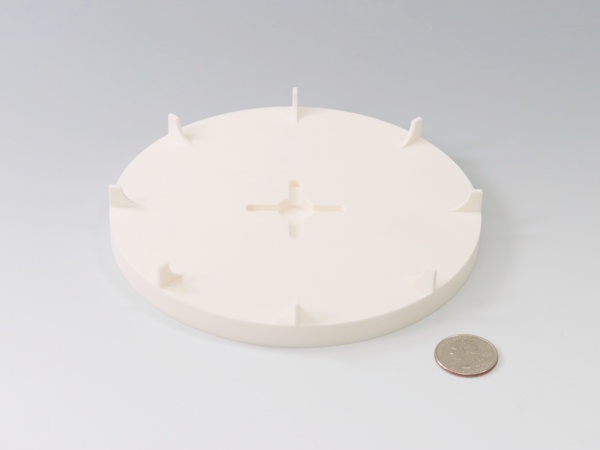

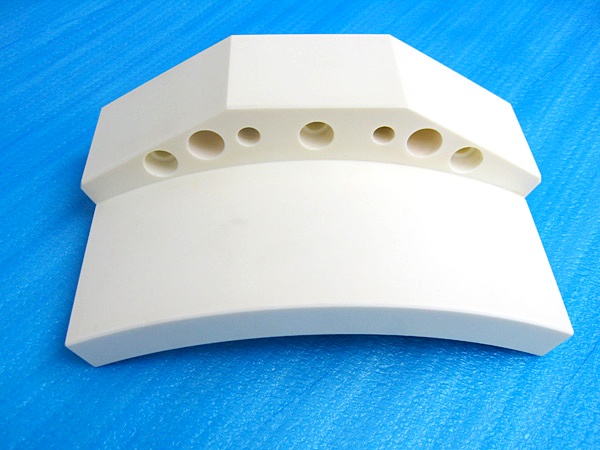

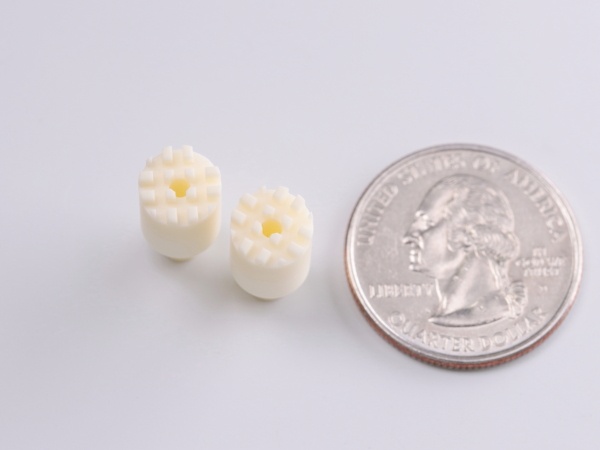

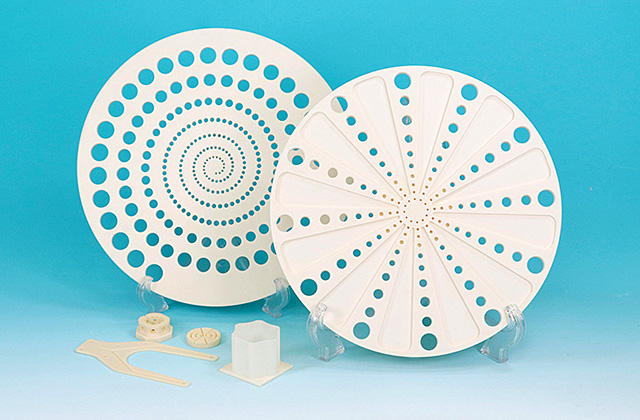

■Precision parts and components ■Jigs & fixtures ■Wear-resistant parts such as nozzles, pumps, valves and thread/wire guides. ■Heat insulation parts ■Heat spreaders ■Crucibles & crucible liners ■Electric insulation parts ■High temperature electrical insulators ■Parts used in reactive gas environments such as gas distributors / showerheads, and chamber liners ■Parts for plasma chambers ■Cylinders and pistons |

| High Temperature Resistance & Low Thermal Expansion |

Alumina has excellent thermal stability up to 1300 ℃. Because it is an oxide ceramic material, it can be used in oxidizing atmospheres at high temperatures. Its low coefficient of thermal expansion makes it ideal for high temperature applications where dimensional stability is required. |

|

| High Dielectric Strength | Alumina has excellent dielectric properties. | |

| Good Chemical Resistance | Alumina has excellent corrosion resistance. It resists attack by most gases including acid gases. It is also plasma resistant. | |

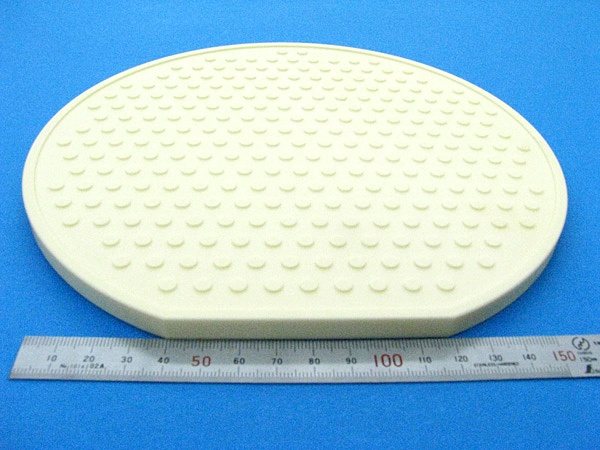

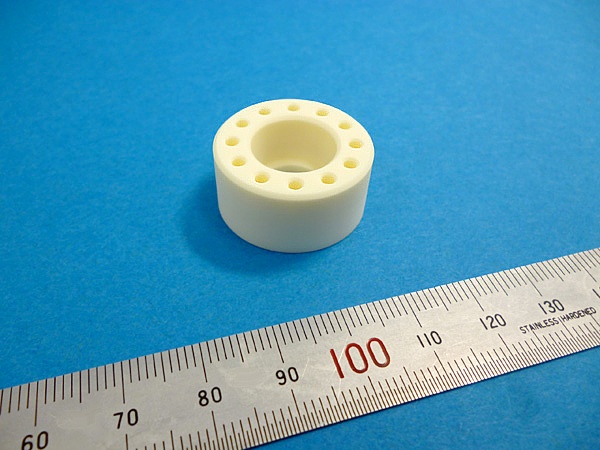

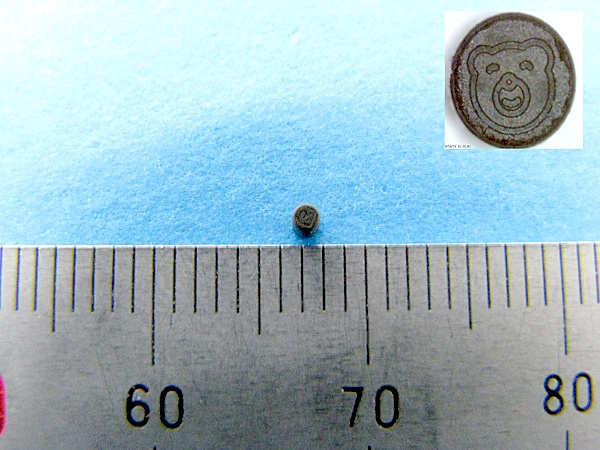

| Good Machinability | Alumina has a good machinability compared to other engineering ceramics. Because it has been a popular ceramic material, we have extensive experience in machining it. Machining to micron accuracy is possible. | |

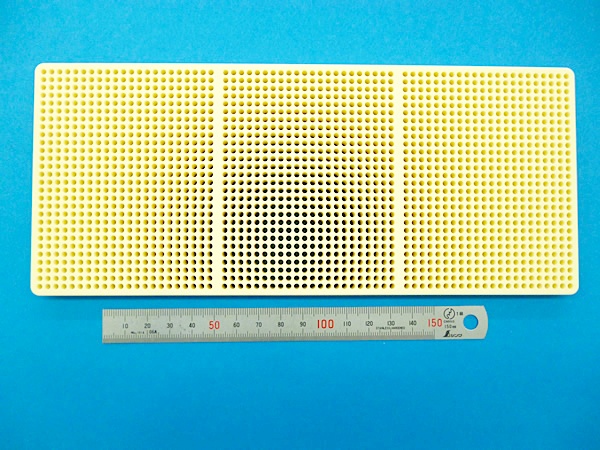

Available Sizes and Machining Capability

| Availability | Sizes(mm) | Machining Capability | Sizes(mm) |

|---|---|---|---|

| Plate | 500×800×30 | Hole diameter | Φ0.1~ |

| Rod | Φ100×300 | Hole depth | ~300 |

| Groove width | 0.05 or more | Max. hole number | 3,000 (approx.) |

| Max. step height | ~70 | Thread size | M1.6~ |

Ceramics List

-

- Alumina(Al₂O₃)

-

Excellent electrical insulation properties , High temperature resistance , Plasma resistance , High hardness , Wear resistance

-

- Aluminum nitride(AlN)

-

High thermal conductivity , High temperature resistance , Low thermal expansion , Excellent electrical insulation properties , Plasma resistant , Corrosion resistant

-

- Zirconia(ZrO2)

-

High fracture toughness , Low thermal conductivity , Wear resistant

-

- Silicon carbide(SiC)

-

High hardness , High thermal conductivity , High mechanical strength , Corrosion resistant

-

- Silicon Nitride (Si3N4)

-

High fracture toughness , Low thermal expansion , Wear resistant , Good thermal shock resistance

-

- Machinable Ceramics

-

Excellent electrical insulation properties , High machinability , High temperature resistance

Top Seiko Co., Ltd.

〒526-0105

1197-4, Hosoe-cho, Nagahama City,

Shiga Pref.,526-0105 Japan

[ Access Map ]