Silicon Carbide (SiC) – Custom Machined Parts

Silicon Carbide has very good mechanical properties and maintains its strength even at extremely high temperatures. It also has excellent resistance to acids, alkalis and molten salts up to 800°C. These exceptional properties make SiC suitable in applications requiring great resistance to wear, thermal shock and corrosion.

Top Seiko has extensive experience in precision machining of both Silicon Carbide and Silicon – Silicon Carbide metal matrix composites (Si-SiC MMCs). Similar to Silicon Carbide, MMCs are excellent materials to use when high thermal conductivity and wear resistance are required.

Silicon Carbide Properties

| Property (Unit) |

Vickers Hardness HV(GPa) |

Flexural Strength (MPa) |

Fracture Toughness (MPam¹/²) |

Coefficient of Thermal Expansion (×10-⁶/℃) |

Thermal Conductivity (W/(m・K)) |

Thermal Shock Resistance(℃) | Dielectric Strength(kv/mm) | Wear Resistance(Blast Abrasion Loss) (μm) |

Chemical Resistance |

|---|---|---|---|---|---|---|---|---|---|

| Chemical Formula | |||||||||

| Silicon Carbide (SiC) |

24 | 500 | 3 | 2.9 | 150 | 450 | 25 | 1.6 (Blast Abrasion Loss) |

Very Good |

Single Crystal SiC Properties

| Property | Color | Mohs Hardness | Density (g/㎠) |

CTE (×10-⁶/℃) |

Resistivity Ω・cm |

Thermal Conductivity | Band Gap | Breakdown Electric Field |

|---|---|---|---|---|---|---|---|---|

| Type | ||||||||

| 4H-SiC N |

Deep Green | 9.2 | 3.21 | (4-5)x10-⁶/K | 0.015~0.028 | 420 W/m・K | 3.23eV | (3-5)x10⁶V/cm |

| 4H-SiC V |

Beige | 9.2 | 3.21 | (4-5)x10-⁶/K | >1x10⁵Ω | 490 W/m・K | 3.23eV | (3-5)x10⁶V/cm |

Silicon Carbide – Key Properties & Popular Applications

| Key Properties | Applications | |

|---|---|---|

| High Hardness Wear Resistance | Due to its high hardness, SiC is extremely resistant to scratches and abrasions. |

■Parts requiring high level of scratch resistance such as wafer carriers and wafer tray supports ■Turbine components ■Blast nozzles ■Mechanical seals & Bearings |

|

High Thermal Stability ■High temperature strength ■Low thermal expansion ■High thermal conductivity ■High thermal shock resistance |

SiC can maintain its strength to very high temperatures. It is extremely resistant to thermal shock due to its excellent combination of high thermal conductivity, low thermal expansion and high strength, and can withstand rapid heating and cooling. |

■Parts requiring high stability and shape retention at high temperatures ■Heat transfer components used at high temperatures such as heaters, heat sinks and heat exchangers |

| Very Good Chemical Resistance | SiC is highly resistant to acids, alkali and reactive gases. |

■Parts used in chemical environments ■Parts subject to deposit removal with acids or alkali. |

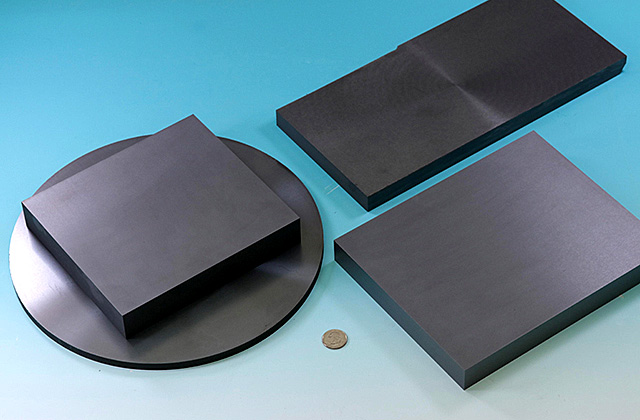

Available Sizes and Machining Capability

| Availability | Sizes(mm) | Machining Capability | Sizes(mm) |

|---|---|---|---|

| Plate | Φ400×t20 | Hole diameter | Φ0.1 or more |

| Rod | Φ50×300 | Hole depth | 20D(if less thanΦ1.5)、200(if less thanΦ1.5) |

| Groove width | 0.1 or more | Max. hole number | 100 |

| Max. Groove(pocket) depth | 30 | Thread size | M2 or more |

Silicon Carbide Custom Machined Parts

- まだ記事はありません。

Ceramics List

-

- Alumina(Al₂O₃)

-

Excellent electrical insulation properties , High temperature resistance , Plasma resistance , High hardness , Wear resistance

-

- Aluminum nitride(AlN)

-

High thermal conductivity , High temperature resistance , Low thermal expansion , Excellent electrical insulation properties , Plasma resistant , Corrosion resistant

-

- Zirconia(ZrO2)

-

High fracture toughness , Low thermal conductivity , Wear resistant

-

- Silicon carbide(SiC)

-

High hardness , High thermal conductivity , High mechanical strength , Corrosion resistant

-

- Silicon Nitride (Si3N4)

-

High fracture toughness , Low thermal expansion , Wear resistant , Good thermal shock resistance

-

- Machinable Ceramics

-

Excellent electrical insulation properties , High machinability , High temperature resistance

Top Seiko Co., Ltd.

〒526-0105

1197-4, Hosoe-cho, Nagahama City,

Shiga Pref.,526-0105 Japan

[ Access Map ]