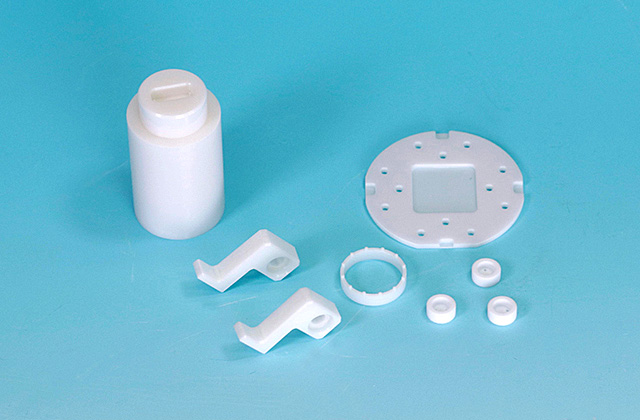

Zirconia (ZrO2) – Custom Machined Parts

Zirconium Dioxide, commonly known as Zirconia, is a high-performance ceramic material which exhibits excellent mechanical properties such as high hardness and fracture toughness. This makes zirconia ideal for a variety of wear resistance applications.

It is difficult to manufacture zirconia in large sizes compared to other oxide materials like alumina. In addition, zirconia is a relatively expensive material, and its use is usually limited to small parts / components which require high bending strength and resistance to fracture, chipping and cracking.

Zirconia Properties

| Property (Unit) |

Vickers Hardness HV(GPa) |

Flexural Strength (MPa) |

Fracture Toughness (MPam¹/²) |

Max Use Temperature℃) | Coefficient of Thermal Expansion (×10-⁶/℃) |

Thermal Conductivity (W/(m・K)) |

Thermal Shock Resistance(℃) | Chemical Resistance |

|---|---|---|---|---|---|---|---|---|

| Chemical Formula | ||||||||

| ZrO₂ | 13 | 1000 | 6 | Not suitable for very high temperature applications. | 7.7 | 3 | 280 | Good |

Zirconia – Key Properties & Popular Applications

| Key Properties | Applications | |

|---|---|---|

| High Strength | Zirconia is an exceptionally strong ceramic. Due to its high bending strength and fracture toughness, it resists cracking, bending or breaking. It can also withstand severe impacts and heavy loads. |

■High load-bearing parts ■High impact-resistant parts ■Cutting tools such as blades and knives |

| Low Thermal Conductivity | Zirconia is an excellent thermal insulator due to its very low thermal conductivity. | ■Heat insulation parts |

| Good Chemical Property | Zirconia resists acid and alkali attack. | ■Pump parts & valve components |

| Excellent Wear Resistance | Zirconia is a popular material for parts used in high friction environments. | ■Wear-resistant parts ■Pistons & liners |

Available Sizes and Machining Capability

| Availability | Sizes(mm) | Machining Capability | Sizes(mm) |

|---|---|---|---|

| Plate | Φ300×30 | Hole diameter | Φ0.2 or more |

| Rod | Φ50×300 | Hole depth | 150 or less |

| Groove width | 0.1 or more | Max. hole number | 100 |

| Max. Groove(pocket) depth | 30 | Thread size | M2 or more |

Zirconia Custom Machined Parts

- まだ記事はありません。

Ceramics List

-

- Alumina(Al₂O₃)

-

Excellent electrical insulation properties , High temperature resistance , Plasma resistance , High hardness , Wear resistance

-

- Aluminum nitride(AlN)

-

High thermal conductivity , High temperature resistance , Low thermal expansion , Excellent electrical insulation properties , Plasma resistant , Corrosion resistant

-

- Zirconia(ZrO2)

-

High fracture toughness , Low thermal conductivity , Wear resistant

-

- Silicon carbide(SiC)

-

High hardness , High thermal conductivity , High mechanical strength , Corrosion resistant

-

- Silicon Nitride (Si3N4)

-

High fracture toughness , Low thermal expansion , Wear resistant , Good thermal shock resistance

-

- Machinable Ceramics

-

Excellent electrical insulation properties , High machinability , High temperature resistance

Top Seiko Co., Ltd.

〒526-0105

1197-4, Hosoe-cho, Nagahama City,

Shiga Pref.,526-0105 Japan

[ Access Map ]