“TOP Machining Technology” – Chapter 1 (Cont.11)

2022.12.15

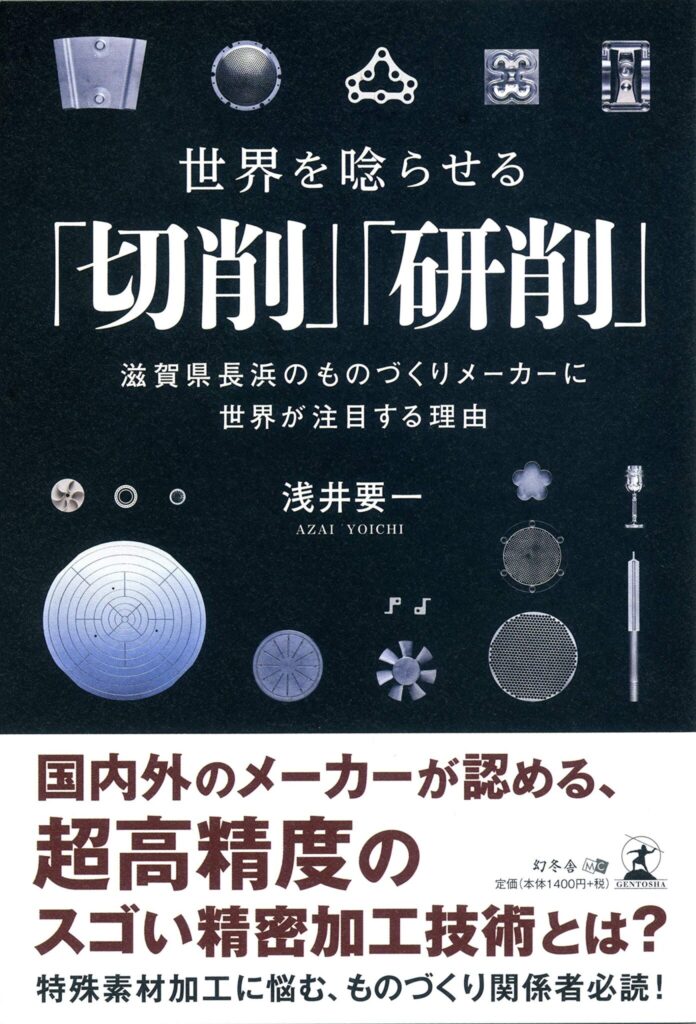

The more diversified materials become, the more cutting and grinding processes enter an unknown world.

Adopting a new material means that the new material must be processed so that it can be used as a base element for a product or part. However, as materials become more specialized and diversified, a new challenge has emerged: they are difficult to process. In the case of the previously mentioned automotive industry, the challenge of joining dissimilar materials is cited as being difficult. Both general steel and high-tensile steel (high-tensile steel plate) materials, which have high workability, can be easily joined to each other by welding. However, aluminum, which is increasingly used in the automotive industry, has high thermal conductivity, making it unsuitable for welding that applies heat, such as spot welding. Joining aluminum and steel has therefore been a challenge.

In recent years, manufacturers have been developing technologies for joining aluminum and steel, but it is inherently difficult to connect dissimilar materials and maintain the required strength, which requires a special joining technique. Composite materials such as resin and CFRP are similarly difficult to join with different materials. For this reason, they are mainly used in parts that are independent of the mechanism, such as hoods and suspension arms.

By the way, in 2015, our company appeared on NHK’s popular program “Super Waza!”. The theme was “The Ultimate Showdown of Joining Different Materials”. While strong bonding between aluminum and cemented carbide was considered impossible, our company competed for tensile strength by joining cemented carbide and aluminum with screws, while our opponents used “brazing technology” to melt and join metals together. Regardless of the result, both companies put their wits about them, engaged in friendly competition, and did their best. The joining of different materials is so difficult that it even became a TV project.

Magnesium, which is increasingly used in automobiles along with aluminum, is another nonferrous metal that is difficult to process. This is because magnesium has low ductility (the ability to be stretched without breaking) due to its unique crystalline structure, and plastic working (a processing method in which force is applied to a material to deform it into a desired shape) at room temperature is difficult. In addition, not only in the automotive industry, but also in the manufacturing industry as a whole, there is a growing trend toward a greater demand for a truly diverse range of materials.